Iindawo zokuchaneka kwegranite zidlala indima ebalulekileyo ekulinganisweni koomatshini be-VMM (Vision Measuring Machine). Oomatshini be-VMM basetyenziselwa ukulinganisa ngokuchanekileyo nangokuchanekileyo izinto ezahlukeneyo kumashishini afana neemoto, i-aerospace, kunye nemveliso. Ukuchaneka nokuthembeka kwezi zilinganiso kuxhomekeke kakhulu ekuzinzeni nasekuchanekeni kwezinto zomatshini, ngakumbi iindawo zokuchaneka kwegranite.

I-Granite lukhetho oludumileyo lweendawo ezichanekileyo kwiimashini ze-VMM ngenxa yozinzo lwayo olukhethekileyo, ukuqina, kunye nokumelana nokuguguleka nokubola. Ezi mpawu zenza ukuba ibe yinto efanelekileyo yokuqinisekisa ukuchaneka nokuthembeka kwemilinganiselo ethathwa ziimashini ze-VMM. Ukusetyenziswa kweendawo ezichanekileyo ze-granite kwiimashini ze-VMM kunceda ukunciphisa imiphumo yezinto zangaphandle ezifana nokuguquguquka kobushushu kunye nokungcangcazela, okunokuthi ngenye indlela kuthintele ukuchaneka kwemilinganiselo.

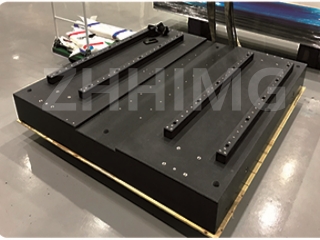

Iindawo ezichanekileyo zegranite kwiimashini zeVMM, ezifana neziseko zegranite kunye nezigaba zegranite, zibonelela ngesiseko esizinzileyo nesiqinileyo sezixhobo ezihambayo kunye neenkqubo zokulinganisa zomatshini. Olu zinzo lubalulekile ekufezekiseni imilinganiselo echanekileyo nephindaphindwayo, ingakumbi xa kujongwana nokunyamezelana okuqinileyo kunye nejometri ezintsonkothileyo. Uzinzo oluphezulu lwegranite luqinisekisa ukuba umatshini ugcina ulungelelwaniso lwawo ngokuhamba kwexesha, nto leyo enciphisa isidingo sokulungiswa rhoqo kunye nokugcinwa.

Ngaphezu koko, i-granite ekhula ngobushushu obuphantsi inceda ekunciphiseni imiphumo yokutshintsha kobushushu ekuchanekeni komatshini, nto leyo eyenza ukuba ifaneleke ukusetyenziswa kwiindawo ezahlukeneyo zoshishino. Iimpawu zokudambisa zegranite nazo zinegalelo ekunciphiseni impembelelo yokungcangcazela kunye nokuphazamiseka kwangaphandle, nto leyo ephucula ngakumbi ukuchaneka kokulinganisa.

Ukuqukumbela, iindawo ezichanekileyo zegranite zidlala indima ebalulekileyo ekulinganisweni kweemashini zeVMM ngokubonelela ngozinzo, ukuqina, kunye nokuchaneka okufunekayo ukuze kulinganiswe ngokuchanekileyo. Ukusetyenziswa kwazo kuqinisekisa ukuba oomatshini beVMM banokunikezela rhoqo idatha yokulinganisa ethembekileyo nesemgangathweni ophezulu, nto leyo eyenza zibe zizixhobo ezibalulekileyo kumashishini ahlukeneyo apho ukuchaneka kunye nokuchaneka kubaluleke kakhulu. Njengoko iteknoloji iqhubeka ihambela phambili, kulindeleke ukuba imfuno yeendawo ezichanekileyo zegranite kwiimashini zeVMM ikhule, nto leyo egxininisa ngakumbi ukubaluleka kwazo kwicandelo le-metrology kunye nolawulo lomgangatho.

Ixesha leposi: Julayi-02-2024