Kwishishini lokucubungula iglasi, ukuchaneka kunye nokuzinza kwezixhobo zokusika iglasi kumisela ngokuthe ngqo umgangatho wemveliso kunye nokusebenza kakuhle kwemveliso. Iziseko zegranite zidlala indima ebalulekileyo kwizixhobo zokusika iglasi, ikakhulu ngenxa yeempawu zazo ezizodwa nezibalaseleyo.

Uzinzo olugqwesileyo luqinisekisa ukuchaneka kokusika

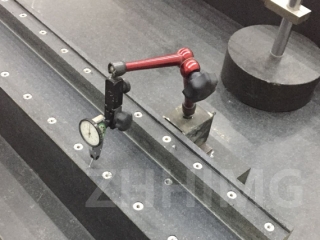

Ukusikwa kweglasi kuneemfuno ezichanekileyo kakhulu. Nokuba kuthe tye kancinci kunokukhokelela ekukhuculweni kwemveliso. Isiseko segranite senziwe ngexesha elide lejoloji, sinesakhiwo sangaphakathi esixineneyo nesifanayo. I-coefficient yayo yokwandiswa kobushushu iphantsi kakhulu, kuphela (4-8) × 10⁻⁶/℃, kwaye ubungakanani bayo abutshintshi kangako xa ubushushu butshintsha. Ngexesha lenkqubo yokusikwa kweglasi, ubushushu obuveliswa kukusebenza kwezixhobo kunye nokuguquguquka kobushushu kwindawo yokusebenzela abuyi kubangela ukuguquguquka okucacileyo kobushushu besiseko segranite. Ingasoloko ibonelela ngenkxaso ezinzileyo nethembekileyo kwisixhobo sokusika, iqinisekisa indawo echanekileyo yesixhobo sokusika okanye umqadi welaser. Iglasi esikiweyo inemiphetho ecocekileyo kunye nobukhulu obuchanekileyo, iphucula kakhulu imveliso yeemveliso.

Ukuqina okuqinileyo kuyamelana nempembelelo yamandla angaphandle

Xa izixhobo zokusika iglasi zisebenza, ukudibana phakathi kweendawo zokusika kunye neglasi kuya kuvelisa amandla athile okuchukumisa, kwaye kwangaxeshanye, ukuhamba kwezixhobo ngokwazo kuya kubangela ukungcangcazela. I-Granite iqinile ngokwesitayile kwaye inobulukhuni obuhle kakhulu. Ubulukhuni bayo bunokufikelela kwi-6-7 kwisikali se-Mohs kwaye inamandla aphezulu okucinezela. Oku kwenza isiseko se-granite sikwazi ukumelana ngokulula namandla ahlukeneyo angaphandle ngexesha lenkqubo yokusika kwaye akunakwenzeka ukuba sonakale okanye sonakale. Xa kuthelekiswa nezinye iziseko zesinyithi ezinokuguqulwa kukudinwa phantsi kwamandla angaphandle ahlala ixesha elide naqhelekileyo, iziseko ze-granite, ezinobulukhuni bazo obuqinileyo, zihlala zigcina isakhiwo esizinzileyo, ziqinisekisa ukusebenza okuzinzileyo kwexesha elide kwezixhobo kunye nokunciphisa ukugcinwa kwezixhobo kunye nexesha lokungasebenzi okubangelwa ziingxaki zesiseko.

Ukusebenza kakuhle kokudambisa kunciphisa ukuphazamiseka kokungcangcazela

Ukungcangcazela yenye yezinto ezibalulekileyo ezichaphazela ukuchaneka kokusikwa kweglasi. Ukuba ukungcangcazela okwenziwa ngexesha lokusebenza kwezixhobo akunakuncitshiswa ngexesha, kuya kubangela ukuba isixhobo sokusika okanye umqadi welaser unyikime, okubangela iingxaki ezifana neendawo zokusika ezingalinganiyo kunye nemigca yokusika engalinganiyo. I-Granite inamandla amahle okudambisa. Ulwakhiwo lwayo oluntsonkothileyo lweeminerali kunye neembobo ezincinci ngaphakathi zifana nezifunxi zendalo zokungcangcazela. Xa ukungcangcazela kudluliselwa kwisiseko segranite, ezi zakhiwo kunye neembobo zinokuguqula ngokukhawuleza amandla okungcangcazela abe ngamandla obushushu kwaye ziwachithe, zinciphise kakhulu ukuphazamiseka kokungcangcazela kwinkqubo yokusika. Umzekelo, kwizixhobo zokusika iglasi yelaser ekhawulezayo, isiseko segranite sinokucinezela ngempumelelo ukungcangcazela kwentloko yelaser, siqinisekise ukuba umqadi welaser usebenza ngokuzinzileyo kumphezulu weglasi kwaye ufezekisa iziphumo zokusika ezichanekileyo nezisemgangathweni ophezulu.

Ukumelana nokuguguleka kakuhle kwandisa ubomi benkonzo yezixhobo

Ngexesha lokusebenza kwexesha elide kwezixhobo zokusika iglasi, isiseko siya kuvelisa ukungqubana okuthile nezixhobo zokusika, izixhobo zeglasi, njl. I-Granite inokumelana nokuguguleka okuhle ngenxa yobunzima bayo obuphezulu kunye nesakhiwo sayo esixineneyo. Thatha umphezulu webhentshi yokusika njengomzekelo. Yenziwe nge-granite kwaye inokumelana nokungqubana okubangelwa kukubekwa rhoqo kweglasi kunye nokuhamba kwezinto zokusika, kwaye ayinakwenzeka ukuba ibe neengxaki ezifana nokuguguleka kunye nokukrweleka. Oku akuqinisekisi nje kuphela ukuba umphezulu wesiseko uthe tyaba kwaye kugcina ukuchaneka okuphezulu kwezixhobo, kodwa kwandisa kakhulu ubomi benkonzo yesiseko kunye nezixhobo zokusika iglasi zonke, kunciphisa iindleko zokuhlaziya izixhobo zamashishini.

Ayisebenzi ngemagnethi, ithintela ukuphazamiseka kwe-electromagnetic kwinkqubo yokusika

Kwezinye izixhobo zokusika iglasi eziphambili, izixhobo ze-elektroniki kunye neesensor ezichanekileyo zisetyenziselwa ukulawula ukuchaneka kokusika kunye nendawo. Imagnethi enokubakho yesiseko sesinyithi inokubangela ukuphazamiseka kwe-electromagnetic kwezi zixhobo ze-elektroniki, okuchaphazela ukusebenza kwazo okuqhelekileyo kunye nokuchaneka kokudluliselwa kwesignali. Kwelinye icala, igranite yinto engeyontsimbi engenamagnethi kwaye ayizukubangela naluphi na ukuphazamiseka kwe-electromagnetic kwiinkqubo ze-elektroniki ngaphakathi kwesixhobo. Oku kwenza izixhobo zokusika iglasi zisebenze kwindawo ezinzileyo ye-electromagnetic, ukuqinisekisa ukuhanjiswa ngokuchanekileyo kwemiqondiso eyahlukeneyo yokulawula ngexesha lenkqubo yokusika, kunye nokuphucula ngakumbi ukuchaneka kokusika kunye nokuthembeka kokusebenza kwesixhobo.

Ukuqukumbela, iziseko zegranite, ngenxa yokuzinza kwazo okubalaseleyo, ukuqina kwazo okuqinileyo, ukusebenza kakuhle kokudambisa, ukumelana nokuguguleka kakuhle kunye nokungasebenzisi magnetism, ziye zaba lolona khetho lufanelekileyo kwizixhobo zokusika iglasi, zibonelela ngesiqinisekiso esiqinileyo kwishishini lokucubungula iglasi ukuze lifezekise imveliso echanekileyo nefanelekileyo.

Ixesha leposi: Meyi-19-2025