Xa sihamba kwizakhiwo zakudala okanye kwiindawo zokusebenzela zokwenza izinto ngokuchanekileyo, sihlala sidibana nezinto ezibonakala zingaguquki ngexesha kunye notshintsho lokusingqongileyo: i-granite. Ukususela kumanyathelo ezikhumbuzo zembali eziye zathatha amanyathelo angenakubalwa ukuya kumaqonga achanekileyo kwiilebhu ezigcina ukuchaneka kwinqanaba le-micron, izinto ze-granite zibonakala zizinzo lwazo olumangalisayo. Kodwa yintoni eyenza eli litye lendalo lingaguquki kangaka, nokuba phantsi kweemeko ezinzima? Makhe sihlolisise imvelaphi yejoloji, iimpawu zezinto, kunye nokusetyenziswa okusebenzayo okwenza i-granite ibe yinto ebalulekileyo kushishino lwanamhlanje kunye noyilo lwezakhiwo.

Ummangaliso WeJiyoloji: I-Howranite Yakha Ulwakhiwo Lwayo Olungaguqukiyo

Ngaphantsi komphezulu woMhlaba, utshintsho oluhamba kancinci luye lwenzeka kangangezigidi zeminyaka. I-Granite, ilitye eliyi-igneous elenziwe ngokuphola okucothayo kunye nokuqina kwe-magma, lizinze kakhulu kwisakhiwo esikhethekileyo sekristale esakhiwe ngeli xesha lenkqubo yokwakheka ende. Ngokungafaniyo namatye e-sedimentary, akhiwe ngamaleko kwaye athanda ukuqhekeka, okanye amatye e-metamorphic, anokuba neendiza ezibuthathaka ezivela kwi-recrystallization ebangelwa luxinzelelo, i-granite yakha nzulu ngaphantsi komhlaba apho i-magma iphola kancinci kancinci, ivumela iikristale ezinkulu zeminerali ukuba zikhule kwaye zidibane ngokuqinileyo.

Le matrix yekristale edibeneyo ngokuyintloko iqulathe iiminerali ezintathu: iquartz (20-40%), ifeldspar (40-60%), kunye ne mica (5-10%). I Quartz, enye yezona minerali zixhaphakileyo ezinzima ezinobunzima be Mohs obuyi 7, inika ukumelana okungaqhelekanga kokukrwela. I Feldspar, enobunzima bayo obuphantsi kodwa obuninzi, isebenza njenge "umqolo" welitye, ngelixa i mica yongeza ukuguquguquka ngaphandle kokunciphisa amandla. Xa zidibene, ezi minerali zenza izinto ezidityanisiweyo ezimelana namandla okucinezelwa kunye noxinzelelo ngcono kakhulu kunezinye iindlela ezenziwe ngabantu.

Inkqubo yokupholisa kancinci ayidali nje kuphela iikristale ezinkulu kodwa ikwasusa uxinzelelo lwangaphakathi olunokubangela ukuguquka kwamatye apholiswe ngokukhawuleza. Xa i-magma iphola kancinci, iiminerali zinexesha lokuzilungelelanisa zibe yimeko ezinzileyo, zinciphisa iziphene kunye namanqaku abuthathaka. Le mbali yejoloji inika i-granite isakhiwo esifanayo esiphendula ngokuqikelelweyo kutshintsho lobushushu kunye noxinzelelo loomatshini, okwenza ukuba ilungele ukusetyenziswa ngokuchanekileyo apho uzinzo lobukhulu lubalulekile.

Ngaphaya koBulukhuni: Iingenelo ezininzi zeenxalenye zeGranite

Nangona ubulukhuni budla ngokuba luphawu lokuqala olunxulunyaniswa negranite, ukusetyenziswa kwayo kudlulela ngaphaya kokuxhathisa ukukrwela. Enye yezona mpawu zixabisekileyo zegranite kukwanda kwayo okuphantsi kobushushu, ngokuqhelekileyo malunga ne-8-9 x 10^-6 nge °C. Oku kuthetha ukuba nangona kukho ukuguquguquka okukhulu kobushushu, igranite itshintsha ubukhulu bayo kancinci xa ithelekiswa neentsimbi ezifana nentsimbi (11-13 x 10^-6 nge °C) okanye isinyithi esityhidiweyo (10-12 x 10^-6 nge °C). Kwiindawo ezifana neevenkile zoomatshini okanye iilebhu apho amaqondo obushushu anokwahluka nge-10-20°C imihla ngemihla, olu zinzo luqinisekisa ukuba amaqonga egranite agcina ukuchaneka kwawo apho umphezulu wesinyithi unokugoba okanye ujijeke.

Ukumelana neekhemikhali yenye inzuzo ephambili. Ulwakhiwo oluxineneyo lwegranite kunye nokwakheka kweeminerali kuyenza imelane kakhulu nee-asidi, ii-alkali, kunye nezinyibilikisi ze-organic ezinokugqwala umphezulu wesinyithi. Le mpawu ichaza ukusetyenziswa kwayo ngokubanzi kwizityalo zokucubungula iikhemikhali nakwiilebhu, apho ukuchitheka kwayo kungenakuphepheka. Ngokungafaniyo neesinyithi, igranite ayigqwali okanye ayinyibilikisi, isusa imfuneko yokukhusela okanye ukulungiswa rhoqo.

Ukungatsali magnetization luphawu olubalulekileyo kwizicelo zokulinganisa ngokuchanekileyo. Ngokungafaniyo nentsimbi ephoswe ngesinyithi, enokuba yimagnethi kwaye iphazamise izixhobo ezibuthathaka, ukwakheka kwezimbiwa zegranite akunamagnethi ngokwemvelo. Oku kwenza iipleyiti zomphezulu wegranite zibe lolona khetho lukhethwayo lokulinganisa izinzwa zemagnethi kunye nezixhobo zokwenza apho ukuphazamiseka kwemagnethi kunokuphazamisa ukusebenza.

Iimpawu zendalo zokudambisa ukungcangcazela kwegranite ziyamangalisa ngokufanayo. Isakhiwo sekristale esidibeneyo sichitha amandla okungcangcazela ngempumelelo ngakumbi kunesinyithi esiqinileyo, nto leyo eyenza amaqonga egranite afaneleke kakhulu kwi-machining echanekileyo kunye nokusetyenziswa kwe-optical apho ukungcangcazela okuncinci kunokuchaphazela iziphumo. Lo mthamo wokudambisa, kunye namandla aphezulu okuxinzelela (ngesiqhelo yi-150-250 MPa), uvumela igranite ukuba ixhase imithwalo enzima ngaphandle kokungcangcazela okanye ukuguqulwa okubonakalayo.

Ukusuka kwiiTempile zamandulo ukuya kwiifektri zanamhlanje: Ukusetyenziswa okuguquguqukayo kweGranite

Uhambo lweGranite ukusuka kwiindawo zokumba imigodi ukuya kubuchwepheshe obuphambili bubungqina bokusebenza kwayo okungapheliyo. Kwizakhiwo, ukuqina kwayo kuye kwabonakaliswa zizakhiwo ezifana neGreat Pyramid yaseGiza, apho iibhloko zegranite ziye zamelana nokuvezwa kwendalo iminyaka engaphezu kwama-4,500. Abayili bezakhiwo banamhlanje bayaqhubeka beyixabisa igranite kungekuphela nje ngenxa yokuhlala kwayo ixesha elide kodwa nangokusebenziseka kwayo okubonakalayo, besebenzisa iislabs ezicociweyo kuyo yonke into ukusuka kwiifacades ezinde ukuya kwiindawo zangaphakathi zodidi oluphezulu.

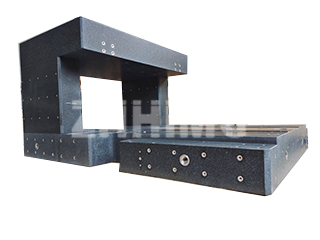

Kwicandelo lezoshishino, i-granite itshintshe indlela ekwenziwa ngayo izinto ngokuchanekileyo. Njengeendawo zokubhekisa ekuhlolweni nasekulinganisweni, iipleyiti zomphezulu we-granite zibonelela nge-datum ezinzileyo, ethe tyaba egcina ukuchaneka kwayo kangangeminyaka emininzi. I-Granite and Marble Manufacturers Association ibika ukuba amaqonga e-granite agcinwe kakuhle anokugcina ukuthamba kwawo ngaphakathi kwe-0.0001 intshi ngenyawo ukuya kuthi ga kwiminyaka engama-50, edlula kakhulu ixesha lokusetyenziswa kwezinye iindlela zesinyithi ezidityanisiweyo ezidla ngokufuna ukukhuhla kwakhona rhoqo emva kweminyaka emi-5-10.

Ishishini le-semiconductor lixhomekeke kakhulu kwizixhobo ze-granite zokuhlola i-wafer kunye nezixhobo zokwenza. Ukuchaneka okugqithisileyo okufunekayo kwimveliso ye-microchip—edla ngokulinganiswa ngee-nanometers—kufuna isiseko esizinzileyo esingayi kuguquka phantsi kweemeko ze-vacuum okanye ukujikeleza kobushushu. Amandla e-granite okugcina uzinzo olulinganayo kwinqanaba le-sub-micron ayenze yaba yinto ebalulekileyo kweli candelo lobuchwepheshe obuphezulu.

Nokuba kusetyenziswe izinto ezingalindelekanga, i-granite iyaqhubeka nokuzibonakalisa ukuba ixabisekile. Kwiinkqubo zamandla avuselelekayo, iziseko ze-granite zixhasa ukulandelela ilanga, zigcina ulungelelwano nelanga nangona kukho imithwalo yomoya kunye notshintsho lobushushu. Kwizixhobo zonyango, iipropati ze-granite zokungcangcazela ziqinisekisa uzinzo lweenkqubo zomfanekiso ezikumgangatho ophezulu ezifana noomatshini be-MRI.

I-Granite vs. Ezinye iindlela: Kutheni Ilitye Lendalo Lisasebenza Kakhulu Kwizinto Ezenziwe Ngumntu

Kwixesha lezinto ezidityanisiweyo eziphambili kunye nezinto ezenziwe ngobunjineli, umntu unokuzibuza ukuba kutheni i-granite yendalo isalokhu iyinto ekhethwayo kwizicelo ezibalulekileyo. Impendulo ikukudibanisa okukhethekileyo kweempawu ezinzima ukuziphinda-phinda ngokwemvelo. Ngelixa izinto ezifana nee-polymers eziqinisiweyo ze-carbon fiber zibonelela ngamanani aphezulu okuqina-ubunzima, azinawo amandla okudambisa i-granite kunye nokumelana nokonakaliswa kwendalo. Iimveliso zamatye ezenziwe ngobunjineli, ezidibanisa amatye atyumkileyo kunye nezihlanganisi ze-resin, zihlala zisilela ukuhambelana nomgangatho wesakhiwo se-granite yendalo, ingakumbi phantsi koxinzelelo lobushushu.

Isinyithi esixonxiweyo, esisetyenziswe ixesha elide njengesixhobo somphezulu esibhekisayo, sineengxaki ezininzi xa kuthelekiswa ne-granite. Ukwanda okuphezulu kwe-iron thermal coefficient kwenza ukuba ibe sesichengeni sokugqwetheka okubangelwa bubushushu. Ikwafuna ukulungiswa rhoqo ukuze kuthintelwe ukugqwala kwaye kufuneka iphinde ikhuhlwe rhoqo ukuze kugcinwe isicaba. Uphononongo olwenziwe yi-American Society of Mechanical Engineers lufumanise ukuba iipleyiti zomphezulu we-granite zigcina ukuchaneka kwazo kungcono ngama-37% kuneepleyiti zesinyithi ezixonxiweyo kwixesha leminyaka eli-10 kwiindawo eziqhelekileyo zokuvelisa.

Izinto zeseramikhi zikhuphisana negranite, ezinobunzima obufanayo kunye nokumelana neekhemikhali. Nangona kunjalo, iiseramikhi zihlala zibuthathaka kwaye ziqhekezeke, nto leyo eyenza zingafaneleki ukusetyenziswa kwimithwalo enzima. Ixabiso lezinto zeseramikhi ezichanekileyo kakhulu likwaphezulu kakhulu kunelegranite, ingakumbi kwiindawo ezinkulu.

Mhlawumbi eyona ngxoxo inamandla ngegranite kukuzinza kwayo. Njengezinto zendalo, igranite ifuna ukucutshungulwa okuncinci xa kuthelekiswa nezinye iindlela ezenziwe ngobunjineli. Iindlela zanamhlanje zokumba imigodi ziye zanciphisa impembelelo kwindalo, kwaye ubude bexesha legranite buthetha ukuba izinto azidingi ukutshintshwa, nto leyo enciphisa inkunkuma kumjikelo wobomi bemveliso. Kwixesha apho ukuzinza kwezinto kubaluleke ngakumbi, imvelaphi yendalo kunye nokuqina kwegranite kunika iingenelo ezibalulekileyo kwindalo.

Ikamva leGranite: Uyilo olutsha ekuHlaziyweni nasekuSetyenzisweni

Nangona iipropati ezisisiseko zegranite zixatyiswe kangangeenkulungwane, izinto ezintsha zakutshanje kubuchwepheshe bokucubungula ziyandisa ukusetyenziswa kwayo kwaye ziphucula ukusebenza kwayo. Iisarha zentsimbi yedayimani eziphambili zivumela ukusika ngokuchanekileyo, ukunciphisa inkunkuma yezinto kunye nokwenza kube lula ukusika izinto ezintsonkothileyo. Iinkqubo zokugaya nokupolisha ezilawulwa yikhompyutha zinokufikelela ekugqityweni komphezulu ngokunyamezelana okuthe tyaba okuqinileyo njenge-0.00001 intshi ngenyawo, okuvula amathuba amatsha kwimveliso echanekileyo kakhulu.

Enye into enomdla kakhulu kukusetyenziswa kwegranite kwiinkqubo zokwenziwa kwezinto ezongeziweyo. Nangona ingaprintwa ngokwayo, igranite inika isiseko esizinzileyo esifunekayo kwiiprinta ze-3D ezinkulu ezivelisa izinto ezinobunzima obuqinileyo. Iimpawu zokudambisa ukungcangcazela kwegranite zinceda ukuqinisekisa ukubekwa kwamaleko rhoqo, ziphucula umgangatho weendawo eziprintiweyo.

Kwicandelo lamandla avuselelekayo, abaphandi bahlola amandla egranite kwiinkqubo zokugcina amandla. Ubunzima bayo obuphezulu bobushushu kunye nozinzo lwayo kwenza ukuba ifaneleke kwiindawo zokugcina amandla obushushu, apho amandla agqithisileyo anokugcinwa njengobushushu aze afunyanwe xa kufuneka. Ubuninzi begranite kunye nexabiso eliphantsi xa kuthelekiswa nezixhobo zokugcina ubushushu ezikhethekileyo zinokwenza obu buchwephesha bufikeleleke ngakumbi.

Ishishini leziko ledatha likwafumanisa iindlela ezintsha zokusebenzisa igranite. Ngenxa yokwanda koxinano lwezixhobo zekhompyutha, ukulawula ukwanda kobushushu kwiirakhi zeseva kuye kwaba yinto ebalulekileyo. Iireyili zokufaka igranite zigcina ulungelelwaniso oluchanekileyo phakathi kwezinto, zinciphisa ukuguguleka kwezihlanganisi kwaye ziphucula ukuthembeka kwenkqubo. Ukumelana nomlilo kwendalo kwegranite kwandisa ukhuseleko lweziko ledatha.

Njengoko sijonge kwikamva, kuyacaca ukuba i-granite iya kuqhubeka nokudlala indima ebalulekileyo kubuchwepheshe nolwakhiwo. Indibaniselwano yayo eyahlukileyo yeempawu—eyenziwe kwiminyaka yezigidi zeenkqubo zejoloji—inika izisombululo kwimingeni ezisasokola ukuyijongana nayo izixhobo zanamhlanje. Ukususela kwiiphiramidi zamandulo ukuya kwizixhobo zekhompyutha ye-quantum, i-granite ihlala iyinto evala umsantsa phakathi kokugqibelela okucothayo kwendalo kunye nomnqweno woluntu wokuchaneka nokuqina.

Isiphelo: Ukutsala Okungapheliyo Kwezinto Zobunjineli Bomhlaba

Izinto zegranite zimi njengobungqina bobuchule bobunjineli bendalo, zibonelela ngomxube ongaqhelekanga wokuzinza, ukuqina, kunye nokuguquguquka okuye kwaxatyiswa kangangeenkulungwane. Ukususela ekuchanekeni kwezixhobo zelebhu ukuya kubukhulu bemisebenzi yobugcisa yokwakha, igranite iyaqhubeka nokuzibonakalisa ukubaluleka kwayo kwizicelo apho ukusebenza kunye nobude bexesha kubaluleke kakhulu.

Imfihlo yokuzinza kwegranite ikwimvelaphi yayo yejoloji—inkqubo yokwenza izinto ecothayo neyayicwangcisiweyo edala isakhiwo sekristale esidibeneyo esingenakuthelekiswa nezinye izinto ezenziwe ngumntu. Olu lwakhiwo lwendalo lunika igranite ukumelana kwayo okugqwesileyo nokuguquguquka, ukwanda kobushushu, ukuhlaselwa ngamakhemikhali, kunye nokuguguleka, nto leyo eyenza ukuba ibe yinto ekhethwayo kwizicelo ezibalulekileyo kumashishini onke.

Njengoko ubuchwepheshe buqhubela phambili, sifumana iindlela ezintsha zokusebenzisa iipropati zegranite kunye nokoyisa imida yayo ngokuphucula ukucubungula kunye noyilo. Sekunjalo, ukutsala okusisiseko kwegranite kuhlala kusekelwe kwimvelaphi yayo yendalo kunye nezigidi zeminyaka ezakha iimpawu zayo ezikhethekileyo. Kwihlabathi eligxile ngakumbi ekuzinzeni nasekusebenzeni, igranite inika indibaniselwano engaqhelekanga yoxanduva lokusingqongileyo kunye nobuhle bobuchwephesha.

Kwiinjineli, abakhi bezakhiwo, kunye nabavelisi abafuna izinto ezinokumelana novavanyo lwexesha ngelixa besenza umsebenzi ongapheliyo, i-granite isengumgangatho wegolide. Ibali layo lidibene nenkqubela phambili yabantu, ukusuka kwimpucuko yamandulo eyayiqaphela ukuqina kwayo ukuya kumashishini anamhlanje axhomekeke ekuchanekeni kwayo. Njengoko siqhubeka sityhala imida yetekhnoloji kunye nolwakhiwo, i-granite ngokungathandabuzekiyo iya kuhlala iliqabane elibalulekileyo ekwakheni ikamva elichanekileyo, elihlala ixesha elide, nelizinzileyo.

Ixesha lokuthumela: Novemba-06-2025