Ukusukela ukuchaneka yeyona nto iphambili ekufumaneni ulwazi lwesayensi kunye nobunjineli obuphambili. Kwindawo yanamhlanje yelabhoratri, ingakumbi ezo zigxile kwizilingo zomzimba ezifuna amandla afana novavanyo lwe-mechanics, isayensi yezinto ezibonakalayo, kunye nohlalutyo lokungcangcazela, isiseko apho lonke uvavanyo lusekelwe khona sihlala sisona sizathu sibalulekileyo sokuqinisekisa ukuthembeka kwedatha. Umbuzo olula, "Kutheni iPrecision Granite Surface Plate isisisombululo esifanelekileyo?" utyhila ukudibana okunzulu kwesayensi yezinto ezibonakalayo, i-metrology, kunye nobunjineli obusebenzayo.

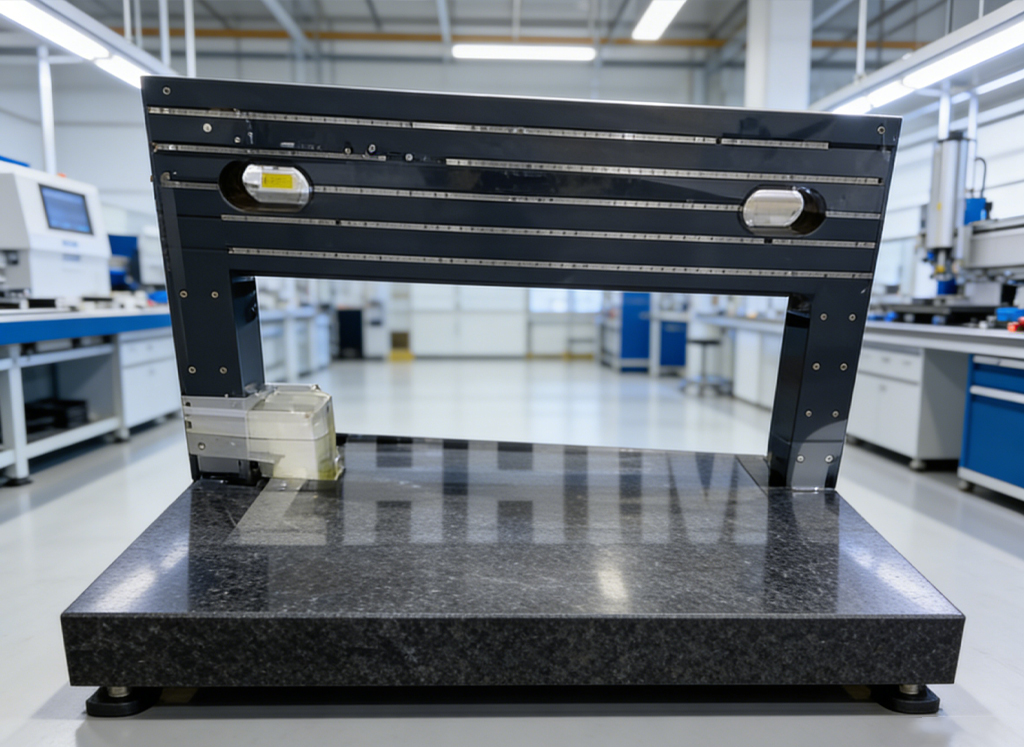

Eli asilolitye nje elicwebezelisiwe; lisiseko esenziwe ngobuchule, umlinganiselo wokuba tyaba, kunye nenxalenye yoomatshini engasebenziyo evumela ngokusisiseko ukubala okuchanekileyo kakhulu kunye novavanyo lwesayensi oluthembekileyo.

Ingxaki yeSiseko Esingagqibelelanga: Kutheni iMigangatho yeConcrete kunye neeTheyibhile zeNsimbi Zingaphumeleli

Ngaphambi kokuba sijonge iimpawu zegranite, kubalulekile ukuqonda imingeni ekhoyo ekusebenziseni iindawo zelebhu eziqhelekileyo. Ibhentshi yokusebenzela yentsimbi eqhelekileyo okanye umgangatho wekhonkrithi, nokuba ubonakala uqinile kangakanani, unemida ebalulekileyo xa ujongene nomlinganiselo omncinci, ukusetyenziswa kwamandla, okanye uvavanyo olutshintshatshintshayo:

-

Ukudluliselwa kokungcangcazela: Intsimbi inomsindo omkhulu. Nasiphi na ingxolo yokusingqongileyo, ukuhamba ngeenyawo, okanye ukuduma koomatshini kudluliselwa lula kwaye kwandiswe kwitafile yentsimbi, oku kungenisa ingxolo kwiitransducers zamandla abuthathaka okanye ii-accelerometers ngexesha lovavanyo lokungcangcazela. Umgangatho wekhonkrithi, nangona umkhulu, usadlulisela ingxolo yenyikima kunye neyolwakhiwo oluphantsi.

-

Ukungazinzi kobushushu: Iintsimbi (ezifana nentsimbi okanye i-aluminium) zine-coefficient ephezulu yokwandiswa kobushushu (CTE). Nokuba kukutshintshatshintsha kobushushu okuncinci kwilebhu kunokubangela ukuba isiseko sigobe okanye sande ngendlela enokulinganiswa, nto leyo ebeka emngciphekweni ngoko nangoko ukuthembeka kokulungelelaniswa okubuthathaka kwiiseti zovavanyo lwe-mechanics.

-

Impazamo yeJiyometri (Ukuthamba): Ukufikelela ekuthambaleni kokwenyani kumphezulu omkhulu wesinyithi kuyabiza kwaye kunzima ukukugcina ngenxa yoxinzelelo lwangaphakathi kunye nemida yokwenziwa. Kwiimvavanyo ezifuna ukulinganiswa ngokupheleleyo kwezixhobo zokulinganisa, iigeyiji zokuphakama, okanye izixhobo ze-optical, oku kungachaneki kwejiyometri okungaphakathi kuyimpazamo ebulalayo.

-

Ukuphazamiseka kweMagnetic kunye ne-Electrical: Izixhobo ezininzi eziphambili, ingakumbi ezo zisebenzisa ii-eddy current sensors okanye ii-high-sensitivity force gauges, zichaphazeleka lula zii-magnetic okanye ii-electrical fields, nto leyo eyenza ukuba izinto ze-ferromagnetic ezifana neetafile zentsimbi zingafaneleki.

Isisombululo seGranite: Isayensi yezinto ezibonakalayo idibana neMetrology

Ukwamkelwa kwe-ZHHIMG® Black Granite—eyaziwa ngokukodwa ngeempawu zayo zomzimba eziphezulu nezixineneyo—njengezinto ezisisiseko zePrecision Granite Surface Plates kujongana ngqo nokusombulula le mida, nto leyo eyenza ukuba ibe sisixhobo esibalulekileyo se-metrology kwiilabhoratri zomzimba.

1. Isalathiso Esipheleleyo: Ukuchaneka kweJiyometri Okungalinganiyo

Umsebenzi ophambili we-Ipleyiti yomphezulu weGranitekukusebenza njenge-datum egqibeleleyo, isicwangciso sereferensi yethiyori apho zonke izilinganiso zisekelwe khona.

-

Ukuthe tye nokuLula okuKhethekileyo: Ngokusebenzisa ubuchule bokulala kunye nezandla ezinobuchule zeengcaphephe—njengabo baseZHHIMG Group abafikelela kwinqanaba le-nanometer lokuthe tyaba—amaqonga egranite ahlangabezana nemigangatho yamazwe ngamazwe engqongqo (umz., i-DIN, i-ASME, i-JIS). Eli nqanaba lokuchaneka okuqinisekisiweyo akunakwenzeka ukuliphinda rhoqo okanye ngexabiso elifanelekileyo ngezinye izixhobo.

-

Uzinzo Lwemilinganiselo: I-Granite yinto e-isotropic, oko kuthetha ukuba iipropati zayo ziyafana kuzo zonke iindlela, kwaye ayinazo iingcinezelo zangaphakathi eziqhelekileyo kwisinyithi esenziwe ngomatshini. Olu zinzo luqinisekisa ukuba ipleyiti igcina ukuchaneka kwayo kwejometri kwiminyaka emininzi yokusetyenziswa, nto leyo enciphisa isidingo sokulungiswa kwakhona rhoqo nokubizayo.

2. Ukudambisa ukungcangcazela kunye nokuqina: Ukuqinisekisa ukuba idatha icocekile

Kwiimvavanyo ezinje ngovavanyo lokungcangcazela okanye uhlalutyo lokudinwa kwezinto eziguqukayo, ukususa ingxolo yoomatshini engafunekiyo kubaluleke kakhulu.

-

I-Superior Damping Coefficient: I-granite enobunzima obuphezulu, ngakumbi i-3100 kg/m³ ZHHIMG® Black Granite, ibonakalisa ukungqubana okuphezulu kwangaphakathi. Olu mgangatho luyivumela ukuba ifunxe amandla oomatshini kwaye isuse ukungcangcazela ngokukhawuleza nangokufanelekileyo kunentsimbi okanye isinyithi. Isiphumo singumhlaba ococekileyo nozolileyo woomatshini, ovumela ii-sensors kunye nee-force gauges ukuba zibambe idatha yovavanyo yokwenyani ngaphandle kokuphazamiseka.

-

I-High Modulus of Elasticity (Rigidity): Nangona inamandla okunyibilikisa, i-granite inobunzima obuphezulu. Olu bunzima buphezulu lunciphisa ukuphambuka phantsi kwemithwalo enzima edla ngokunxulunyaniswa neefreyimu zovavanyo lwe-mechanics, izixhobo ezinkulu ze-optical, okanye iinkqubo ze-CMM (Coordinate Measuring Machine). Ukungabikho kokuphambuka phantsi komthwalo kubalulekile ekugcineni ulungelelwaniso olubalulekileyo phakathi kwezixhobo zovavanyo kunye nezinto eziphandwayo.

3. Ukungabi Namandla Kwe-Thermal NeeKhemikhali: Indawo Ezinzileyo

Imeko yelabhoratri ayilawuleki ngokugqibeleleyo, nto leyo eyenza ukuba ukuphendula kwezinto kube yinto ebalulekileyo.

-

I-Coefficient ephantsi yoKwandiswa kobushushu (CTE): I-CTE ephantsi yeGranite ithetha ukuba nokutshintshatshintsha kobushushu okuncinci kuvelisa utshintsho oluncinci kakhulu, umahluko omkhulu kwisinyithi esinokwanda okanye sinciphe kakhulu. Olu zinzo lobushushu olungasebenziyo lubalulekile ekubanjweni kwedatha ethembekileyo kwixesha elide lovavanyo.

-

Ayina-Hygroscopic kwaye Ayinakonakalisa: I-Granite ayifunxi umswakama kwaye iyakwazi ukumelana nokugqwala okuvela kwiikhemikhali eziqhelekileyo zelebhu kunye nomhlwa. Oku kuyenza ilungele ukusetyenziswa kwiindawo ezahlukeneyo, ukusuka kwiilebhu ezimanzi kakhulu zaselunxwemeni ukuya kumagumbi acocekileyo, ukuqinisekisa ukusebenza kakuhle kwexesha elide kunye nobuhle ngaphandle kwesidingo sokukhusela.

-

I-Non-Magnetic: Njengento engeyo-ferromagnetic, i-granite ibalulekile kwiisetingi ezibandakanya ii-magnetic sensors, ii-linear motors, okanye izixhobo ze-electron beam ezibuthathaka, okususa umngcipheko wokuphazamiseka kwe-magnetic okungcolisa idatha.

I-ZHHIMG®: Ukuseta uMgangatho weHlabathi woBuchule

Xa ukhetha iPrecisionIpleyiti yomphezulu weGranitekwilebhu yakho, umthombo wokuvelisa ubaluleke njengezinto ngokwazo. Iqela le-ZHONGHUI (ZHHIMG®) liqinise isikhundla salo njengenkokeli yehlabathi ngokudibanisa amandla okuvelisa akumgangatho wehlabathi kunye namava obugcisa amashumi eminyaka.

Ukuzinikela kwethu ekufikeleleni kumgangatho ophezulu kubonakaliswa ngoku:

-

Isiqinisekiso soMgangatho esiPheleleyo: I-ZHHIMG® yinkampani yodwa kushishino ephethe iziqinisekiso ze-ISO 9001, ISO 45001, ISO 14001, kunye ne-CE ngaxeshanye, ezibonelela ngesiqinisekiso esiqinisekisiweyo somgangatho, uxanduva lokusingqongileyo, kunye nempilo nokhuseleko emsebenzini.

-

Izakhiwo Ezisemgangathweni: Indawo yethu yokusebenzela yoBushushu obuQhelekileyo kunye nokuFudumala eyi-10,000 m² bubungqina bomgangatho wethu. Esi sakhiwo, sixhotyiswe ngomgangatho womkhosi kunye neempawu eziphambili zokulwa nokungcangcazela, senzelwe ngokukodwa ukuqinisekisa ukuba yonke ipleyiti yomphezulu kunye nenxalenye yegranite ishiya umzi-mveliso wethu uqinisekisiwe kumgangatho ophezulu kangangoko, ulungele ukusetyenziswa ngoko nangoko kwizicelo zoshishino ezifuna kakhulu ukuchaneka.

-

Intsebenziswano Yehlabathi: Ubudlelwane bethu obuqhubekayo namaziko adumileyo afana neYunivesithi yeSizwe yaseSingapore, iYunivesithi yaseStockholm, kunye namaziko ahlukeneyo e-metrology yamazwe ngamazwe (e-UK, eFransi, e-US) bubonisa umzamo wethu oqhubekayo wokuphucula iindlela zokulinganisa kunye nokugcina igunya lobuchwepheshe elipheleleyo kwicandelo loomatshini abachanekileyo.

Ngaphaya kwePlate yomphezulu: Ikamva leeCandelo ezichanekileyo

Imigaqo eyenza ipleyiti yomphezulu ibaluleke kakhulu ifikelela ngqo kwiGranite Components kunye neGranite Machine Structures zethu eziphambili. Nokuba yiGranite Gantry Base eqinileyo kakhulu yomatshini we-semiconductor lithography okanye i-Granite Air Bearing assembly edibeneyo, ezi zinto zenza isiseko soshishino oluchanekileyo kakhulu. Ngokubonelela ngesiseko esiqinileyo nesizinzileyo, i-ZHHIMG® ivumela iinjineli ukuba zityhale imida yokuchaneka okunokwenzeka kwizixhobo zeCMM, iinkqubo zokucubungula i-laser, kunye namaqonga okuhlola akhawulezayo.

Isiphelo: Tyala imali kwiNgqibelelo yeDatha yakho

Kwilabhoratri ezinikele kuvavanyo lwe-mechanics, uvavanyo lokungcangcazela, okanye naluphi na uhlobo lovavanyo oluphezulu, iPrecision Granite Surface Plate ayisiyonto ibalulekileyo—lutyalo-mali oluyimfuneko ekugqibeleleni kwedatha. Ibonelela kuphela ngesalathiso esisebenzayo nesiqinisekisiweyo esinokwahlula uvavanyo kwingxolo yokusingqongileyo ngelixa ngaxeshanye siqinisekisa ukugqibelela kwejometri. Ukukhetha umboneleli oqinisekisiweyo onjengeZHHIMG® kuthetha ukukhetha umlinganiselo othembekileyo kwihlabathi liphela, oxhaswa zizixhobo eziphezulu kunye nokuzibophelela okungagungqiyo kwisigqibo esithi: “Ishishini elichanekileyo alinakuba nzima kakhulu.”

Ixesha leposi: Disemba-16-2025