Kwihlabathi lokhuphiswano lweMold Manufacturing—ingakumbi kwii-injection molds, stamping dies, kunye neepateni zokuphosa ezisetyenziswa kwimoto, izixhobo zonyango, kunye nemveliso ye-elektroniki yabathengi—umda wempazamo awusekho. I-mold engenasiphako sisiqinisekiso sezigidi zeemveliso zokugqibela ezigqibeleleyo. Yonke inkqubo yokwenza i-mold, ukusuka kwi-machining yokuqala ye-computer numerical control (CNC) ukuya kwi-final assembly, ixhomekeke kubuchule bokuqinisekisa ngokuphindaphindiweyo kunye nokubeka iindawo ngokuchanekileyo kwinqanaba le-micron. Le mfuneko isisiseko ichaza isizathu sokuba i-Precision Granite Surface Plate ingabi sisixhobo nje kuphela, kodwa yidatha ebalulekileyo, engagungqiyo yereferensi yoshishino.

Indima yeqonga legranite kweli candelo idlulela ngaphaya kokuhlola umphezulu nje okulula; isebenza njengomlawuli wokugqibela wokuchaneka kwejometri, ivumela iinjineli ezisemgangathweni ukuba ziqinisekise ukuthembeka kobukhulu bezinto ezibalulekileyo zesikhunta, ukuqinisekisa ukutshintshana kunye nokudibana okungenasiphako phakathi kweziqingatha zesikhunta.

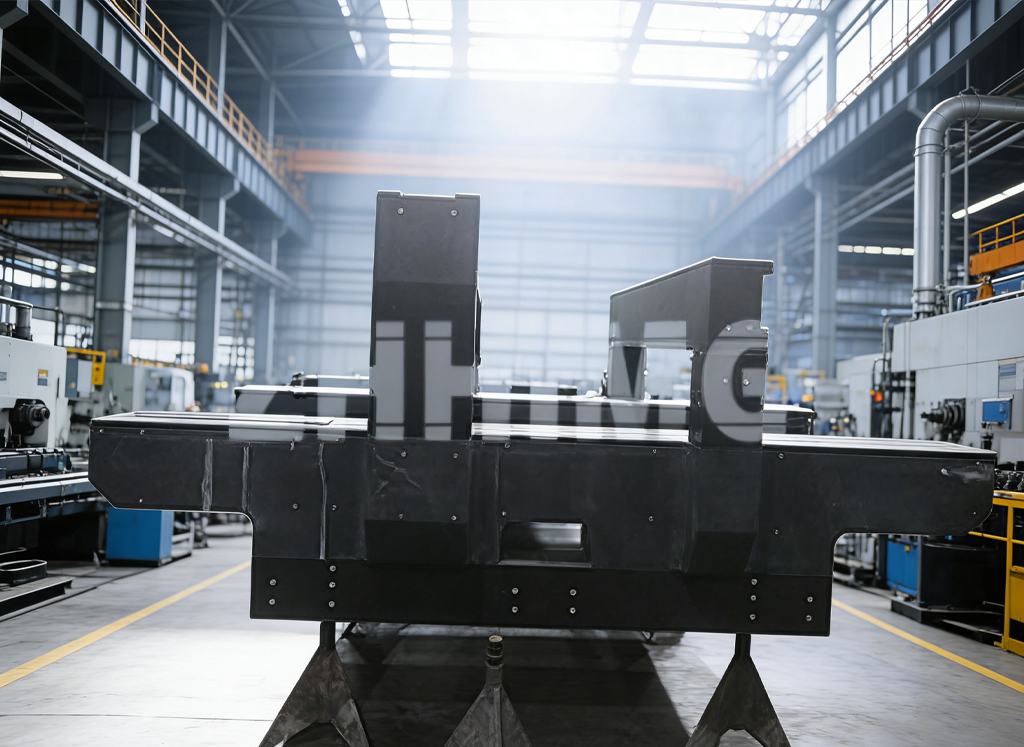

Umngeni Wokwenza Imveliso Yezikhunta: Ukunyaniseka Kwejiyometri Ngesantya Esiphezulu

Izinto ezikwimold, ezifana neengxangxasi, ii-cores, kunye nee-slides ezintsonkothileyo, zihlala zine-geometries ezintsonkothileyo ze-3D, ukunyamezelana okuqinileyo, kunye neendawo ezikhazimlisiweyo kakhulu. Nakuphi na ukusilela kwisakhiwo semold—nokuba kukungalungelelani kakuhle, ukungalingani, okanye ubunzulu obungalunganga—kuya kuguqulela ngokuthe ngqo kwiziphene kuyo yonke inxalenye elandelayo eveliswayo, nto leyo ekhokelela kwilahleko enkulu yemveliso.

Iziseko zokulinganisa zemveli ezenziwe ngentsimbi okanye ngesinyithi esityhidiweyo ziyasokola ukugcina uzinzo olufunekayo ngenxa yezinto ezifana noxinzelelo olushiyekileyo, ukuphendula kobushushu, kunye nokungoneli kokungcangcazela. Abenzi bomngundo bafuna isixhobo semetrology esibonelela:

-

Ukuqina Okupheleleyo: Yindawo eqinisekisiweyo yokujonga apho zonke iindawo eziphakamileyo, ubunzulu, kunye nee-engile zinokujongwa khona.

-

Uzinzo Lwemilinganiselo: Izinto ezingachaphazelekiyo kukutshintshatshintsha kobushushu bomgangatho weworkshop.

-

Ukuzihlukanisa nokungcangcazela: Isiseko esiqinileyo esithintela ukuphazamiseka kokusingqongileyo ekuchaphazeleni izixhobo zokulinganisa ezinobuthathaka ezifana nezikhombisi zedayile, amanqanaba e-elektroniki, okanye ii-probe ze-CMM.

Indima Ebalulekileyo yeGranite: Ukuchaneka kunye nokuhlanganisa

UchanekoIpleyiti yomphezulu weGraniteIjongana nale mingeni ngemisebenzi emibini ephambili kwivenkile yokubumba: Ukuhlolwa kokuchaneka kweMold kunye nokuBekwa kweSiseko esiBalulekileyo.

1. Ukuhlolwa kokuchaneka kweMold: Idatha yokwenyani yoMgangatho

Xa kuhlolwa izinto ezahlukeneyo ezenza iseti yesikhunta, ipleyiti yegranite inika isiqinisekiso esiqinileyo nesingenakuphikiswa se-zero-reference plane:

-

Ukuqinisekiswa koBume: I-granite enobunzima obuphezulu, efana ne-ZHHIMG® Black Granite (enobunzima obumalunga ne-3100 kg/m³), inika ubulukhuni obuphezulu, iqinisekisa ukuba ipleyiti ayiphambuki phantsi kobunzima beziseko ezinkulu okanye ezinzima zesikhunta. Oku kuvumela abasebenzi bokuqinisekisa umgangatho ukuba baqinisekise ngokuchanekileyo ukufana, ubume besikwere, kunye nobuthe tyaba besebenzisa iigeyiji zokuphakama, amanqanaba e-elektroniki, kunye neebhloko zegeyiji. Ukuxinana okuphezulu kwangaphakathi kwezinto kuqinisekisa ngakumbi ukuba ukungcangcazela kwendalo akuphazamisi ukufundwa komlinganiselo obuthathaka.

-

Isalathiso se-Optical kunye ne-CMM: Ipleyiti sisiseko esimiselweyo sazo zonke izixhobo ezichanekileyo ezisetyenziswa kwi-Mold Precision Detection, kubandakanya iiCoordinate Measuring Machines (CMM Equipment), iinkqubo zokubona, kunye nee-specific inspection jigs. Ukuthe tyaba kwesiseko se-granite kulawula ngokuthe ngqo ukuchaneka kwe-CMM, okwenza ukusetyenziswa kwee-Grade 00 eziqinisekisiweyo okanye ii-calibration-grade plates kungaxoxiswana ngazo kumsebenzi we-mold onyamezelayo kakhulu.

-

Ukuqina Kobushushu Ukuze Kuthembeke: Njengoko izinto zokubumba ngokwazo zipholile kwinkqubo ye-CNC Machining, ziyancipha. I-Coefficient of Thermal Expansion (CTE) ephantsi kakhulu yegranite iqinisekisa ukuba isiseko sesalathiso ngokwaso sihlala singaguquguquki ngokwemilinganiselo, sibonelela ngeqonga elizinzileyo lokulandelela nokulinganisa utshintsho oluhambelana nokupholisa lwenxalenye ngokuchanekileyo.

2. Ukubekwa kwesiseko kunye nokuhlanganiswa kweCandelo: Ukwakhiwa kokugqibelela

Umgangatho wesikhunta ekugqibeleni umiselwa yindlela izinto zaso ezintsonkothileyo—ii-cores, ii-cavities, ii-runners, kunye nee-ejector pins—ezihambelana ngayo ngokugqibeleleyo ngexesha lokuhlanganiswa. Ipleyiti yegranite yenza kube lula eli nyathelo libalulekileyo:

-

Isalathiso soLungelelaniso: Kwizigaba zokugqibela zokuhlanganiswa kwesikhunta, izinto zihlala zibekwa okwethutyana kwiGranite Platform ukujonga ulungelelwaniso oluthe nkqo nolusecaleni ngaphambi kokuba kufakwe ibholti yokugqibela. Izinto ezikhethekileyo zeGranite ezifana nezikwere, iiparallels, kunye neebhloko ze-V, ezigayiweyo ngendlela efanayo ne-sub-micron njengepleyiti ngokwayo, zisetyenziselwa ukubamba iindawo ezintsonkothileyo ezithe nkqo okanye ezihambelanayo ne-datum plane, ukuqinisekisa ukudibana okungenasiphako kweziqingatha ezimbini zesikhunta.

-

Ukukrwela nokuFakela: Kwizibumba ezindala okanye ezikhethekileyo ezichanekileyo ezifuna ukukrwela ngesandla okanye ukufakelwa ukuze kufezekiswe unxibelelwano olufanelekileyo, ipleyiti yegranite ibonelela ngendawo ebalaseleyo yokubhekisa ekudluliseleni amabala aphezulu kwinxalenye yesikhunta kusetyenziswa i-bluing compound. Ubuthe tyaba kunye nobunzima bezinto ezisetyenzisiweyo kuqinisekisa ukuba inkqubo yokudlulisa icocekile kwaye ichanekile kakhulu.

-

Iziseko Zokuxhoma Ngokwezifiso: Ngaphaya kweepleyiti ezisemgangathweni, iiSystems kunye neziseko zoMatshini weGranite ezenziwe ngokwezifiso zisetyenziswa njengeeplatifomu zokufakela iijigs zokuhlanganisa ngokuchanekileyo. Ezi ndibano zeGranite ezikhethekileyo zibonelela ngesakhiwo esizinzileyo ngokwemilinganiselo esimelana nokugoba kunye nokungcangcazela, okuvumela abahlanganisi ukuba bafikelele kunyamezelo oluqinileyo olufunekayo kwiimolds eziphezulu kunye nezinamanqanaba amaninzi.

Umahluko we-ZHHIMG®: Iqabane ekwenzeni iMold echanekileyo

Kwishishini apho isantya kunye nokuchaneka kubaluleke kakhulu, ukukhethaUmenzi weGranite ochanekileyongegunya lehlabathi kunye namandla angenakuthelekiswa nanto kubalulekile. I-ZHONGHUI Group (ZHHIMG®) iphakamisa umgangatho weGranite Metrology Tools ngoku:

-

Ubuchule obuQinisekisiweyo: Njengenkampani yodwa kushishino ephethe i-ISO 9001, i-ISO 45001, i-IS ngaxeshanye

Isatifikethi se-14001, kunye ne-CE, sibonisa ukuzibophelela okucwangcisiweyo kumgangatho ohambelana nemigangatho ephezulu efunwa yi-mold manufacturing supply chain.

Isatifikethi se-14001, kunye ne-CE, sibonisa ukuzibophelela okucwangcisiweyo kumgangatho ohambelana nemigangatho ephezulu efunwa yi-mold manufacturing supply chain. -

Isikali Sokuvelisa Esingenakuthelekiswa Nanto: Amandla ethu okucubungula izinto ezinkulu zegranite—kuquka iiyunithi enye ukuya kuthi ga kwiitoni ezili-100—kunye neendlela zethu zokuvelisa ezikhawulezayo ziqinisekisa ukuba sinokubonelela ngeeGranite Bases ezinkulu, ezintsonkothileyo, nezinomthamo ophezulu ezifunekayo kumashishini eemoto kunye nee-elektroniki kwihlabathi liphela ngaphandle kokuphazamiseka.

-

Ukusukela Ukugqibelela: Kukhokelwa kukuzibophelela, “Akukho kuqhatha, Akukho kufihla, Akukho kukhohlisa,” kunye nomgaqo-nkqubo womgangatho, “Ishishini elichanekileyo alinakuba nzima kakhulu,” yonke iqonga ligqityiwe kwi-10,000 m² Constant Temperature and Humidity Workshop yethu, ukuqinisekisa ukuchaneka kwayo okuqinisekisiweyo ngaphambi kokuba ifike kwiziko lakho.

Ubunzima bokwenza isikhunta sanamhlanje bufuna izixhobo ezilula ngokwemvelo, ezizinzileyo, nezithembekileyo ngokupheleleyo. I-Precision Granite Surface Plate sisixhobo esisisiseko esinika inyani yejiyometri efunekayo ukuguqula uyilo lwedijithali lube yimfezeko ebonakalayo, iqinisekisa umgangatho kunye nobude bexesha layo yonke isikhunta esiveliswayo.

Ixesha leposi: Disemba-16-2025