Uhambo olungapheliyo lokwenziwa kwezinto ezincinci kumashishini onke—ukusuka ekuvelisweni kwee-semiconductor ukuya kwiibhodi zeesekethe eziprintiweyo eziphambili (ii-PCB) kunye nee-micro-mechanics—luye lwandisa imfuneko ye-metrology echanekileyo nephindaphindwayo. Eyona nto iphambili kolu tshintsho kukukho Izixhobo zokulinganisa ububanzi bomgca ozenzekelayo, isixhobo esibalulekileyo sokulawula umgangatho kunye nokwenza ngcono inkqubo. Ezi nkqubo zintsonkothileyo zihamba ngaphaya kokuhlolwa okulula kwe-optical, zixhomekeke kwiisensa ezisemgangathweni ezingezizo ezonxibelelwano, ii-algorithms eziphambili, kwaye, mhlawumbi eyona nto ibalulekileyo, isiseko sozinzo loomatshini esihlala singaqatshelwa: izinto ze-granite mechanical.

Ukusebenza kwayo yonke into ngesixhobo sokulinganisa esikhawulezayo nesichanekileyo kuxhomekeke ngqo kwiindawo eziyinxalenye yaso. Ngelixa i-optics, iikhamera, kunye nesoftware yokucubungula zitsala ingqalelo, ukuzinza kweqonga elibonakalayo—isakhiwo esibambe iisensa ngokuchanekileyo—yiyo egqiba ukuchaneka okugqibeleleyo okunokufezekiswa. Kulapho ukhetho lobunjineli lwezixhobo zokulinganisa ububanzi bomgca oluzenzekelayo luba yinto ebalulekileyo khona, nto leyo ekhokelela abavelisi abaninzi abaphambili ukuba bakhethe i-granite njengezinto ezikhethwayo kwiziseko, iikholamu, kunye nezigaba ezithwala umoya.

Indima Ebalulekileyo Yozinzo LweeMechanical kwiMetrology

Ukulinganisa ububanzi bomgca ochanekileyo kudla ngokubandakanya ukubona ubungakanani kwi-micrometer nakwi-sub-micrometer. Kule nqanaba, ukuguquguquka okuncinci kwendalo okanye ukungafezeki kwesakhiwo kunokufaka iimpazamo zokulinganisa ezingamkelekanga. Umngeni ophambili kuyo nayiphi na inkqubo ezenzekelayo kukugcina ubudlelwane bendawo phakathi kwesenzi sokulinganisa (ngokuqhelekileyo ikhamera enesisombululo esiphezulu okanye i-laser micrometer) kunye nenxalenye elinganiswayo. Olu budlelwane bubuthathaka busengozini enkulu kwiziganeko ezininzi zomzimba: ukungcangcazela, ukwanda kobushushu, kunye nokushukuma kwesakhiwo.

Izixhobo zemveli ezifana nentsimbi okanye i-aluminium, nangona zomelele, zinemida yazo xa zityhalelwa kwimida yokuchaneka kwe-metrological. Zizii-conductors ezibalaseleyo zobushushu, ezenza zibe sesichengeni sokwanda kobushushu ngokukhawuleza nangokungalinganiyo ngenxa yotshintsho kubushushu obuphakathi okanye ubushushu bomatshini wangaphakathi. Ngaphezu koko, amandla azo okudambisa aphantsi athetha ukuba zithumela kwaye zigcina ukungcangcazela, nokuba zivela kwiimoto zangaphakathi, ii-air compressors, okanye oomatshini bomzi-mveliso abakufutshane, nto leyo eguqulela kwintshukumo ye-microscopic ngexesha lomjikelo wokulinganisa obalulekileyo.

I-Granite: Isisombululo Sendalo Sokuchaneka Okugqwesileyo

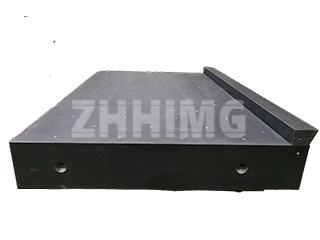

Ukutshintshela kwizixhobo zegranite ezisebenzisa izixhobo zokulinganisa ububanzi bomgca ezizenzekelayo sisigqibo sobunjineli esenziwe ngabom esisekelwe kwiseti ekhethekileyo yezinto ezibonakalayo ezenza ukuba zibe sisiseko esifanelekileyo se-metrology echanekileyo.

Enye yezona nzuzo zibalulekileyo zegranite kukuba i-coefficient yayo ephantsi kakhulu yokwandiswa kobushushu (CTE). Xa ithelekiswa nentsimbi, igranite iyakhula kwaye inciphe ngesantya esicothayo kakhulu kwaye incinci kakhulu xa ivezwa kutshintsho lobushushu. Olu zinzo lobushushu olungaphakathi lubalulekile ekugcineni ulungelelwaniso oluqhubekayo lwejometri yesixhobo, ukuqinisekisa ukuba ukulinganiswa okwenziwe kusasa kuhlala kusebenza imini yonke, nangona imeko-bume yefektri itshintsha.

Ngaphezu koko, igranite inomthamo obalaseleyo wokudambisa ukungcangcazela. Ulwakhiwo lwayo lwendalo lwekristale lusebenza njengomfunxi obalaseleyo wamandla oomatshini. Ngokususa ukungcangcazela ngokukhawuleza, isiseko segranite sinciphisa ukushukuma okuphezulu okunokufiphaza ukufundwa kwe-optical okanye kuthintele ukuchaneka kwendawo yezigaba zokuhamba ngesantya esiphezulu ezidityaniswe neZixhobo zokulinganisa ububanzi bomgca ozenzekelayo. Le nto yokudambisa okuphezulu ivumela izixhobo ukuba zifikelele ekuphuhliseni umlinganiselo ngokukhawuleza ngaphandle kokunciphisa isisombululo kunye nokuchaneka okufunekayo kwiinkqubo zokuvelisa eziphambili.

Olunye uphawu olunomtsalane kukuba igranite ithambile kwaye iqinile ngendlela engaqhelekanga. Ngokusebenzisa iinkqubo ezikhethekileyo zokuleqa nokugqiba, igranite inokufikelela ekunyamezeleni ukuba tyaba komphezulu kuluhlu lwe-sub-micrometer, nto leyo eyenza ukuba ibe yindawo efanelekileyo yeenkqubo ezithwala umoya ngokuchanekileyo ezifuna intshukumo ecwangcisiweyo ngokupheleleyo. Oku kuqina okungokwemvelo kuqinisekisa ukuba iqonga elixhasa i-axis yokulinganisa liyamelana nokuphambuka phantsi kwemithwalo enamandla yezigaba ezenzekelayo, okuqinisekisa ukuthembeka kweplani yesalathiso ngexesha lokusebenza.

I-Nexus yoLawulo lweNtshukumo kunye neGranite

Kwinkqubo ezenzekelayo ngokupheleleyo, isiqwenga somsebenzi kufuneka sihanjiswe kwaye sibekwe ngesantya esiphezulu nangokuchaneka. Izixhobo Zokulinganisa Ububanzi Bomgca Ozenzekelayo zixhomekeke kwizinto eziphambili ezifana neemoto ezithe ngqo kunye neekhowudi ezichanekileyo, kodwa ezi zinto zisebenza kakuhle kuphela njengomphezulu ezisebenza kuwo. Umzekelo, inqanaba lomoya wegranite lisebenzisa ukuqina kunye nokuthe tyaba kwegranite ukufezekisa intshukumo engenakuphikiswa, ephindaphindwayo kakhulu. Ngokusebenzisa iimpawu zezinto zendalo ukuzinza kunye nokuzidibanisa nolawulo oluntsonkothileyo lokuhamba ukuze kube lula, abavelisi benza intsebenziswano eqhuba ukusebenza okungenakuthelekiswa nanto.

Ubunjineli obuchanekileyo bezinto zegranite ngokwazo buyintsimi ekhethekileyo. Abavelisi kufuneka bafumane igranite emnyama ekumgangatho ophezulu, edla ngokuba noxinano oluphezulu kunye nokuvuleka okuphantsi kunezinye iintlobo, baze emva koko bayifake kwiinkqubo zomatshini ezicokisekileyo. Amanqanaba okusila, ukulepha, kunye nokupolisha adla ngokwenziwa phantsi kolawulo oluqinileyo lwemozulu ukuqinisekisa ukuba imveliso yokugqibela ihlangabezana nokunyamezelana okuthe tyaba kakhulu kunye nobunzima obufunekayo kwi-metrology yodidi lwehlabathi.

Ukujonga Ikamva Lokulinganisa Okuzenzakalelayo

Njengoko ijiometri yemveliso iqhubeka nokuncipha kwaye ukunyamezelana kokwenziwa kuqina, iimfuno ezibekwe kwiZixhobo zokulinganisa ububanzi bomgca ozenzekelayo ziya kwanda. Isiseko esibekwe ziinxalenye zegranite ezichanekileyo asikokukhetha nje ilifa; siyimfuneko enokulindelwa kwixesha elizayo. Uphuhliso oluqhubekayo lwale teknoloji luya kubona ukuhlanganiswa kwee-arrays ezinamandla ngakumbi ze-multi-sensor, i-optics yokukhulisa ephezulu, kunye neendlela zokuhamba ezintsonkothileyo. Kuzo zonke iimeko, uzinzo olungagungqiyo kunye ne-inertia yobushushu enikezelwa ziinxalenye ze-granite mechanical ziya kuhlala zisisiseko sokusebenza okuchanekileyo.

Kuyo nayiphi na imveliso esebenza kwindawo yokukhuphisana yemveliso yobuchwepheshe obuphezulu, ukutyala imali kwizixhobo zokulinganisa ezinesiseko segranite esomeleleyo nesizinzileyo kubushushu akuyonto igqithisileyo—yinto ebalulekileyo ekuqinisekiseni ulawulo lomgangatho, ukunciphisa ilahleko yesivuno, kunye nokugcina umda wokukhuphisana. Amandla athuleyo egranite yiyo evumela ii-elektroniki kunye ne-optics ezintsonkothileyo ukuba zenze umsebenzi wazo onzima ngokuchanekileyo nangokungaguquguqukiyo, nto leyo eyenza ukuba ibe liqhawe elingadunyiswanga le-metrology yanamhlanje.

Ixesha leposi: Disemba-03-2025