Kwicandelo eliqhutywa ngokuchanekileyo lemizi-mveliso yanamhlanje—nokuba ziinkampani ezinkulu zeenqwelo-moya zaseMntla Melika okanye iinjineli zeemoto eziphezulu zaseYurophu—kukho inyaniso engathethwayo efundwa ngumphathi womgangatho ngamnye: isoftware yakho ilungile kuphela njengesiseko somzimba sehardware yakho. Ngelixa icala ledijithali le-metrology lifumana ingqalelo enkulu, idabi lokwenyani lokuchaneka liyaphumelela okanye lilahleke kwisayensi yezinto ezibonakalayo yomatshini ngokwawo. Xa sijongana nezinto ezifuna ukuchaneka kwe-sub-micron, ulwakhiwo lomzimba lweumatshini wokulinganisa olungelelanisiweyoiba yeyona nto ibalulekileyo kule ngxaki. Isikhokelela kumbuzo osisiseko kuye nawuphi na umenzi ofuna ukuphucula indawo yakhe: kwindawo ezaliswe kukungcangcazela nokuguquguquka kobushushu, uqinisekisa njani ukuba imilinganiselo yakho ihlala iphelele?

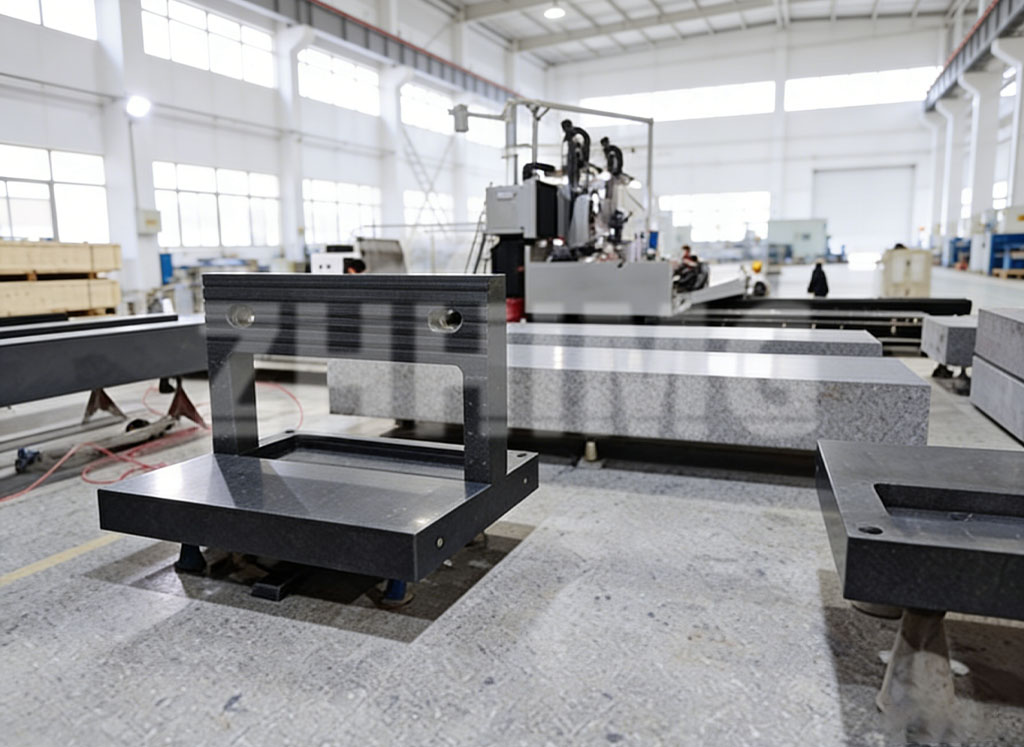

Ukuzama ukulinganisa okugqibeleleyo kuqala ukusuka ekuqaleni, ngokoqobo. Kwabo basebenza ngezinto ezinkulu ezifana neebhloko zeenjini, amacandelo e-fuselage, okanye ii-molds ezinzima zemizi-mveliso, umatshini oqhelekileyo we-bridge udla ngokufikelela kwimida yawo ebonakalayo. Kulapho ibhedi yoMshini wokuMeasuring we-Gantry Coordinate ingena khona kwingxoxo njengomgangatho wegolide wokuhlolwa komthamo ophezulu, nokuchaneka okuphezulu. Ngokungafaniyo noomatshini abancinci abanokuba neengxaki "zokukhala" okunxulumene ne-inertia okanye ukuphambuka kwesakhiwo, inkqubo ye-gantry inika indawo yokusebenza enkulu, ezinzileyo. Kodwa ibhedi yomatshini ingaphezulu nje kwendawo yokuseta inxalenye; liqonga elicwangcisiweyo ngobuchule elenzelwe ukwahlula inkqubo yokulinganisa kwisiphithiphithi somgangatho wefektri.

Eyona nto iphakamisa inkqubo ekumgangatho wehlabathi ukusuka kweqhelekileyo kukukhetha izinto ezisetyenziswa kumphezulu wayo okhokelayo. Abavelisi abaninzi baye bayeka ukusebenzisa iireli zentsimbi okanye ze-aluminium zemveli bakhetha eziisiporo segraniteIsizathu silula: i-granite yimpendulo yendalo kwingxaki yokungazinzi. Ixinene kakhulu, ayichaphazeleki ziziphumo zokubola kwexesha, kwaye ine-coefficient yokwandisa ubushushu ephantsi kakhulu kunezinyithi ezininzi. Xa usenza umjikelo wokulinganisa onzima othatha iiyure, awunakukwazi ukuhlawulela "i-skeleton" yomatshini wakho ukuba ikhule okanye inciphe kuba umoya opholileyo womzi-mveliso ujikeleza okanye ucime. Ngokusebenzisa i-granite rail, umatshini ugcina indlela eqinileyo, ethe tye esebenza njengesalathiso esingaguqukiyo kuyo yonke indawo yedatha ebanjiweyo.

Nangona kunjalo, neyona granite ilungileyo ilawulwa yimithetho yokungqubana ukuba ayiphathwanga kakuhle. Kulapho ke “umlingo” wobunjineli wokwenyani uvela khona kwi-metrology ephezulu. Ukuze kufezekiswe intshukumo yolwelo, elula nefunekayo ekuskeni ngesantya esiphezulu, abasunguli abaphambili baye baphucula ukusetyenziswa kweiindlela zokuhamba ngesantya segraniteEzi nkqubo zisebenzisa ifilimu encinci yomoya ocinezelweyo—ngokufuthi ubukhulu bayo buzii-microns ezimbalwa kuphela—ukuphakamisa izinto ezihambayo zomatshini wokulinganisa ohambelanayo kumphezulu wegranite. Le teknoloji yokuthwala umoya iqinisekisa ukuba akukho nxibelelwano loomatshini phakathi kwebhulorho ehambayo kunye nomzila omileyo. Ngenxa yokuba akukho kungqubana, akukho kukrweleka, kwaye okubaluleke ngakumbi, akukho kuveliswa kobushushu. Olu “kudada” luvumela i-gantry ukuba ityibilike ngenqanaba lokuphindaphindeka elingenakwenzeka ngokwasemzimbeni ngeerola zoomatshini okanye iibheringi zebhola.

Kwiinkampani ezizingca ngokuba phakathi kwababoneleli abaphezulu kwihlabathi liphela, ukuhlanganiswa kwezi mpawu akuyonto ikhethekileyo; yinto efunekayo kwezobuchwepheshe. Xa injineli kwilebhu yobuchwepheshe obuphezulu ijonga iinkcukacha zebhedi yoMshini wokulinganisa iGantry Coordinate, ikhangela inkqubo enokumelana novavanyo lwexesha. Kufuneka yazi ukuba umlinganiselo othatyathwe namhlanje uya kufana nalowo uthatyathwe kwiminyaka emihlanu ukususela ngoku. Ngokudibanisa iipropati zendalo zokudambisa isiseko esikhulu segranite kunye nokuhamba okungenangquzulwano kweendlela zegranite flotation, senza indawo yokulinganisa eyahlulwe ngokupheleleyo kwihlabathi langaphandle.

Ngaphaya kwezixhobo ezibonakalayo, kukho into echaphazela ingqondo kweli nqanaba lokuchaneka. Xa umthengi etyelela indawo aze abone inxalenye ihlolwa kwinkqubo enkulu ye-gantry esekelwe kwi-granite, idlulisela umyalezo wegunya kunye nomgangatho ongagungqiyo. Ixelela umthengi ukuba lo mvelisi akajongi nje le nxalenye; kodwa uyayiqinisekisa ngokuchasene nemigangatho ephezulu yefiziksi kunye nobunjineli. Kwimeko yokhuphiswano lorhwebo lwamazwe ngamazwe, apho ukuthembana yeyona mali ixabisekileyo, ukuba neziseko ezifanelekileyo ze-metrology yingxelo enamandla yenjongo.

Njengoko sisiya phambili kwixesha le-Industry 4.0, indima ye-umatshini wokulinganisa olungelelanisiweyoiza kuqhubeka ikhula. Sibona ukuhlanganiswa okungakumbi kwedatha yexesha langempela, apho umatshini ungabhali nje ukusilela, kodwa uxela kwangaphambili umkhwa. Kodwa nokuba i-AI okanye isoftware iphucuke kangakanani na, iya kuhlala ixhomekeke ekugqibeleleni komatshini. I-granite rail kunye neenkqubo ze-flotation ziiqhawe ezingathethiyo zale nguqu yetekhnoloji. Zibonelela "ngenyaniso" ekufuneka iinkqubo zedijithali zisebenze.

Ekugqibeleni, ukukhetha iqabane le-metrology kuxhomekeke ekuqondeni kwabo le migaqo isisiseko. Kungaphezulu nje kokuthengisa isixhobo; kukubonelela ngesisombululo sexesha elide sokuchaneka. Nokuba ulinganisa isixhobo sezonyango esibuthathaka okanye icandelo elikhulu leenqwelo-moya, injongo ihlala ifana: ukuqiniseka ngokupheleleyo. Ngokutyala imali kwizixhobo ezikumgangatho ophezulu kunye nobuchwepheshe be-flotation obuphambili, abavelisi abathengi nje umatshini—baqinisekisa ikamva lomgangatho wabo wemveliso.

Ixesha leposi: Jan-12-2026