Kwiphulo elingapheliyo lokufumana ii-microchips ezincinci, ezikhawulezayo, nezinamandla ngakumbi, iimfuno ezibekwe kwi-Wafer Processing Equipment ziyanda ukuya kumanqanaba okuchaneka ngaphambili okwakucingelwa ukuba akunakufikelelwa. Njengoko iimpawu zincipha ziye kwinqanaba le-nanometer yenombolo enye, ukuzinza kweqonga lonke lokuvelisa kuba yinto ebalulekileyo. Kulapha, phantsi koluhlu oluntsonkothileyo lwee-laser, amagumbi okucoca, kunye neenkqubo zerobhothi, apho izinto zemvelaphi yamandulo—i-granite yendalo—zivela khona njengento ebalulekileyo kwimpumelelo ye-semiconductor yanamhlanje. Iinkcukacha, ubunjineli, kunye nobonelelo lwezinto ze-granite ze-OEM ezichanekileyo kakhulu kunye nebhedi yomatshini we-granite ye-OEM ayizomfuno zobugcisa kuphela; zisisiseko sokuthembeka kokusebenza.

Indima yesiseko somatshini kuyo nayiphi na inkqubo echanekileyo kukubonelela ngeplani yesalathiso engaguqukiyo nezinzileyo. Kwimeko-bume eguquguqukayo nechanekileyo yokwenza i-semiconductor, apho iinkqubo ezifana ne-lithography, i-etching, kunye ne-deposition zenzeka khona, ukuphambuka okuncinci—nokuba kwinqanaba le-sub-micron—kunokukhokelela ekulahlekelweni yimveliso okukhulu. Ukukhethwa kwezinto zokwakha eziphambili, njengesiseko somatshini se-Wafer Processing Equipment, ke ngoko linyathelo elingenakuphikiswana kuyilo.

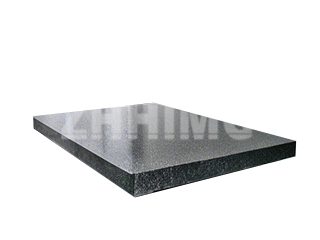

Iingenelo Eziqhelekileyo ZeGranite Yendalo

Kutheni igranite yendalo isebenza ngcono kunezinye izinto ezisetyenzisiweyo ezifana nentsimbi ephosiweyo, intsimbi, okanye ezinye izinto ezidityanisiweyo kolu hlobo lukhethekileyo? Impendulo ikwiimpawu zayo zomzimba ezikhethekileyo, ezindala ngokwemvelo ezifanelekileyo ngokugqibeleleyo kwimeko-bume engenanceba yoomatshini abachanekileyo.

1. Ukudambisa ukungcangcazela okungaqhelekanga (Ukuzahlula kwiNkqubo yoDynamics):

Ukungcangcazela yeyona nto ibangela ukuba i-nanoscale ingasebenzi kakuhle. Nokuba iveliswa ngaphakathi ziimoto kunye nezinto ezihambayo okanye ngaphandle kumgangatho wegumbi lokucoca, naluphi na uqhushululu kufuneka lufunxwe ngokukhawuleza. I-Granite ine-intrinsic damping coefficient ephezulu ngaphakathi—ingcono kakhulu kuneentsimbi. Le propati ithetha ukuba amandla oomatshini anyamalala ngokukhawuleza njengobushushu, ethintela ukuqaqamba kunye nokuqinisekisa ukuba iinkqubo ezibalulekileyo zenziwa kwiqonga elimileyo ngokwenene. Oku kubalulekile ekugcineni indawo echanekileyo kwi-lithography ephucukileyo okanye ukuqinisekisa ukususwa kwezinto ezifanayo ngexesha lokucwangcisa i-chemical mechanical (CMP).

2. Ukwandiswa kobushushu obuphantse bube yiZero (Ukugcina uBulungisa boLungelelaniso):

Izixhobo Zokucubungula I-Wafer zihlala ziquka ukuguquguquka kobushushu, kokubini okungqongileyo kunye nokubangelwa yinkqubo. Izinto zesinyithi ziyanda kwaye zinciphe kakhulu ngotshintsho lobushushu, okukhokelela ekushukumeni kobushushu kunye nokungahambi kakuhle kweenkqubo ze-optical okanye ze-mechanical. I-Granite, ingakumbi i-granite emnyama, ibonisa i-coefficient ephantsi kakhulu yokwandiswa kobushushu (CTE), malunga ne-3×10⁻⁶/℃. Olu zinzo lobushushu luqinisekisa ukuba ukuchaneka kobukhulu bebhedi yomatshini we-granite kunye nezinye izinto ze-granite ze-OEM zihlala zihambelana, kunciphisa iimpazamo zobushushu kwaye kuqinisekisa ukuphindaphindwa komlinganiselo phantsi kweemeko ezahlukeneyo.

3. Ukuqina kunye nokuthamba kokugqibela:

Ngokusebenzisa iindlela eziphambili zokulepha nokupolisha, i-granite yendalo inokufikelela kwi-surface flatness elinganiswa kwii-sub-microns—imfuneko ebalulekileyo kwiindawo ezisetyenziswa kulawulo lokuhamba ngokuchanekileyo. Ngaphezu koko, i-high Young's modulus yayo inika ukuqina okungaqhelekanga kunye nokuguquguquka. Oku kuxhathisa ukuphambuka phantsi komthwalo kubalulekile, njengoko isiseko kufuneka sixhase ii-motors ezinkulu ezithe nkqo, izigaba, kunye nezakhiwo ezintsonkothileyo ze-Wafer Processing Equipment ngaphandle kokuguquguquka okunokulinganiswa, nokuba kungaphezulu kwesithuba esikhulu.

Ubunjineli beKamva: Izixhobo zeGranite ze-OEM kunye neNdibano eNxibeleleneyo

Ukusetyenziswa kwanamhlanje kwegranite kudlulela ngaphaya kweepleyiti zomphezulu ezilula. Abavelisi betekhnoloji ephezulu banamhlanje bafuna izinto zegranite ze-OEM ezintsonkothileyo, ezenzelwe wena. Ezi zinokubandakanya iireli zesikhokelo ezithwala umoya, ii-vacuum chucks ezintsonkothileyo, izinto zesigaba esine-axis ezininzi, kunye neebhloko zokufakela ze-laser kunye ne-optics. Ezi ziqwenga zihlala zisebenza ngomatshini ngeempawu zejiyometri ezintsonkothileyo, kubandakanya imingxunya ebholiweyo yokuhambisa ucingo, izinto ezifakelwe ngentambo zokufakela, kunye ne-dovetails okanye i-slots ezifakwe ngomatshini ngokuchanekileyo kwiinkqubo zokuthwala.

Inkqubo yokwenza indibano epheleleyo yeZixhobo zokuLungisa iWafer iqala ngomatshini omkhulu wegranite. Izinto ezilandelayo zegranite zibotshelelwa okanye zincamathiselwe ngokuchanekileyo kuyo kusetyenziswa iikhompawundi ezisekwe kwi-epoxy eziphambili, inyathelo elibalulekileyo eliqinisekisa ukuba isakhiwo sonke sisebenza njengeyunithi enye, efanayo. Ukuhlanganiswa okuphumelelayo kufuna ingqalelo enzulu kwiinkcukacha:

-

Ukwenziwa ngokwezifiso: Izinto ezisetyenzisiweyo kufuneka zenziwe ngokweemfuno zomthengi ezikhethekileyo, zihlala ziquka ukuhlanganiswa kwezinto ezingezizo i-granite ezifana nemigca yokupholisa kunye nee-sensor mounts ngqo kwisakhiwo.

-

Uqinisekiso loMgangatho: Icandelo ngalinye lifuna ulawulo lomgangatho oluqinileyo, kubandakanya ukuthe tye, ukuqina, kunye nokuqinisekiswa kwesikwere kusetyenziswa ii-CMM kunye nee-interferometer ze-laser, ukuqinisekisa ukuba ziyahlangabezana nemigangatho engqongqo ye-ISO kunye neyamazwe ngamazwe ye-metrology kunye nokuchaneka.

-

Ubudlelwane phakathi kwababoneleli: Ukukhetha umthengisi wezixhobo zegranite ze-OEM bubudlelwane phakathi kwababoneleli. Kufuna ukuqonda okunzulu malunga nokusetyenziswa kwe-semiconductor, ukukwazi ukukhetha ilitye eliluhlaza elikumgangatho ophezulu, kunye nokukwazi ukuvelisa umatshini nokudibanisa izakhiwo ezintsonkothileyo ngokwemilinganiselo ye-nanometer.

Ukuqukumbela, nangona i-microchip egqityiweyo ingummangaliso wobuchule bomntu, ukudalwa kwayo kuxhomekeke ekuzinzeni okuthuleyo okubonelelwa lilitye lendalo. Ukusetyenziswa okuntsonkothileyo kwe-granite njengezinto eziphambili zebhedi yomatshini we-granite kunye nezinye izinto ezikhethekileyo ze-OEM granite yinto ebaluleke kakhulu ekutyhaleni imida ye-miniaturization. Kubavelisi beZixhobo zokuLungiselela iWafer, ukusebenzisana nengcali kwizakhiwo ze-granite ezichanekileyo kakhulu linyathelo lokuqala nelisisiseko lokuqinisekisa umda wokukhuphisana kwimarike ye-semiconductor yehlabathi.

Ixesha leposi: Disemba-01-2025