Ishishini le-semiconductor lisebenza ngomlinganiselo wokuchaneka otyhala imida yobuchule bomntu. Intliziyo yokulawula umgangatho wale shishini—inyathelo lokugqibela nelibalulekileyo ngaphambi kokuba i-chip ibonwe ilungele ukuthengiswa—kukho izinto ezibonakala zilula: i-granite. Ngokukodwa, amaqonga e-precision granite sisisombululo esisetyenziswa kakhulu sokuhlolwa kwe-semiconductor chip, into enokubamangalisa abo bangaphandle kweli candelo. Kwi-ZHONGHUI Group (ZHHIMG®), siyiqonda kakuhle le ntsebenziswano. Ubuchule bethu bokwenza izinto ze-granite ezichanekileyo kakhulu kunye nezixhobo zokulinganisa busenze saba liqabane eliphambili kwezinye zeenkampani eziphambili zehlabathi ze-semiconductor kunye ne-metrology. Ukuxhomekeka kwi-granite kwesi sicelo sibalulekileyo asingombandela wesithethe kodwa yifiziksi kunye nobunjineli obucocekileyo. Kumalunga nokuhlangabezana neseti yeemfuno ezizodwa nezinzima ezingenakufikelelwa zezinye izinto ngempumelelo.

Imfuno Engapheliyo Yokuzinza

Ukuhlolwa kweetshiphusi ze-semiconductor akupheleli nje ekujongeni iziphene; kumalunga nokuqinisekisa ukuba iimpawu ezincinci, ezihlala zilinganiswa ngeenanometers, zenziwe ngokugqibeleleyo. Le nkqubo ibandakanya izixhobo ezintsonkothileyo, ezifana neenkqubo zokuhlola i-optical (AOI) kunye nee-industrial CT scanners, ekufuneka zihlale zizinzile ngokugqibeleleyo ngexesha lokuskena. Nakuphi na ukungcangcazela, ukwanda kobushushu, okanye ukushukuma kwesakhiwo kunokungenisa iimpazamo, okukhokelela kwiziphumo ezingezizo okanye, okubi ngakumbi, iziphene ezingaphoswanga.

Kulapho igranite ikhanya khona. Ngokungafaniyo nesinyithi, esanda kwaye incipha kakhulu xa kutshintshwe ubushushu, igranite inomlinganiselo ophantsi kakhulu wokwanda kobushushu. I-ZHHIMG® Black Granite yethu inoxinano olumalunga ne-3100kg/m3, olubonelela ngozinzo olukhethekileyo lobushushu. Oku kuthetha ukuba iqonga legranite liya kugcina imo yalo kunye nokuba tyaba nakwiindawo apho ubushushu obujikeleze umhlaba butshintsha kancinci. Kwindawo yokusebenzela elawulwa yimozulu efana nesakhiwo sethu se-10,000m2, apho ubushushu bugcinwa khona ngokuchanekileyo komkhosi, uzinzo lwegranite alunakuthelekiswa nanto.

Ngaphezu koko, iimpawu zokudambisa ezibalaseleyo zegranite zibalulekile. Ngokwendalo ifunxa kwaye isasaze ukungcangcazela koomatshini, ikuthintela ukuba kungadluliselwa kwizixhobo zokuhlola ezibuthathaka. Kwisityalo esixakekileyo sokuvelisa esizele ngoomatshini, oku kungcangcazela kokungcangcazela kubalulekile ekugcineni ukuthembeka komlinganiselo. Iiworkshop zethu ziyilwe ngoku engqondweni, ziqulathe imigangatho yekhonkrithi etyebileyo kakhulu kunye nemisele yokulwa nokungcangcazela ukudala imeko-bume apho iingcibi zethu zinokufikelela ngokuchanekileyo kwinqanaba le-nanometer kumsebenzi wazo.

Ukufuna Ubungangamsha Obupheleleyo

Ukuze inkqubo yokuhlola iitshiphusi isebenze, isiseko sayo kufuneka sisondele ngokugqibeleleyo kangangoko kunokwenzeka. Ingcamango "yomphezulu othe tyaba" kule meko ayibonakali kodwa yeyezibalo, ilinganiswa ngezixhobo ezifana ne-Renishaw laser interferometers kunye namanqanaba e-elektroniki eSwiss Wyler. Injongo yomhloli weetshiphusi kukulinganisa ubunzulu betshiphusi ukuya kwii-microns ezimbalwa, okanye neenanometers. Ukuze wenze oku, iqonga ngokwalo kufuneka libe kumgangatho othe tyaba.

I-Granite yinto, ngokusebenzisa iindlela zethu ezikhethekileyo zokuleqa ngesandla, enokusetyenziswa ukuze ifikelele kwinqanaba elithe tyaba elingenakuthelekiswa nanto. Iingcali zethu zobugcisa, uninzi lwazo olunamava angaphezu kweminyaka engama-30, zinengqiqo yokuchukumisa ebavumela ukuba "bazive" ukuphambuka okuthe tyaba kwee-microns ezimbalwa. Olu chukumiso lomntu, kunye nezixhobo zethu ezikumgangatho wehlabathi, lusenza sikwazi ukuvelisa iipleyiti zomphezulu we-granite ezine-nanometer-flatness, nto leyo eyenza ukuba zibe yindawo efanelekileyo yokubhekisa ekulinganisweni nasekuhlolweni. Esi sisiseko apho kwakhiwa khona uvavanyo oluchanekileyo lwe-semiconductor.

Ukujongana neemfuno ezizodwa zoshishino lwe-semiconductor

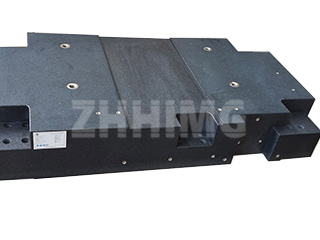

Ishishini le-semiconductor likwaneemfuno ezithile ngaphandle kozinzo kunye nokuthamba. Umzekelo, iinkqubo ezininzi zokuhlola zisebenzisa ii-air bearings ukuze zihambe ngaphandle kokungqubana. I-Granite yindawo efanelekileyo yokubonisa indlela yokuqhuba ii-air bearing ngenxa yokuqina kwayo kunye ne-porosity evumela ukuhamba komoya okucolekileyo, okufanayo. Ii-granite air bearing zethu zenziwe ngokwezifiso ukuqinisekisa ukuhamba okuthe tye nokuchanekileyo, okubalulekileyo ekuhlolweni kwesantya esiphezulu nokuchaneka okuphezulu.

Ukongeza, i-ZHHIMG® Black Granite yethu ayinamagnethi kwaye ayihambisi umbane, nto leyo ibalulekileyo kwizinto ze-elektroniki ezinobuthathaka. Ayiphazamisi amasimi e-electromagnetic ezixhobo zovavanyo okanye itshiphu ngokwayo. Olu hlobo lokungathathi cala luphawu olungenakunikezelwa ngamaqonga amaninzi esinyithi.

Apha kwi-ZHHIMG®, asithengisi nje kuphela i-granite. Sibonelela ngesiseko esibalulekileyo sobuchwepheshe obuphambili kwihlabathi. Ukuzibophelela kwethu kubathengi kukubonelela ngezisombululo ezingenakuqhatha, ezingafihlwayo, ezingalahlekisiyo. Sisebenzisana ngokusondeleyo namaqabane ethu, kuquka iingxilimbela ezifana ne-Samsung kunye namaziko e-metrology, ukuqinisekisa ukuba iimveliso zethu azihlangabezani nje kuphela neemfuno zazo kodwa zinegalelo ekuphuculeni ubuchwepheshe bazo. Kumdlalo obalulekileyo wokuvelisa i-semiconductor, amaqonga e-granite achanekileyo e-ZHHIMG® angamandla athuleyo, angashukumiyo, abonelela ngozinzo kunye nokuchaneka okuzisa izinto ezintsha zekamva ebomini.

Ixesha leposi: Sep-28-2025