Umngeni Ongabonakaliyo Ekulinganisweni Okuphezulu

Kwihlabathi lemveliso ephucukileyo, uvavanyo lwe-elektroniki, kunye nokulinganiswa kwe-sensor, impumelelo ixhomekeke kwinto enye: uzinzo olulinganayo. Sekunjalo, kwanezona seti zinzima zijongene ne-disruptor engathethiyo: i-electromagnetic interference (EMI). Kwiinjineli ezijongene ne-sensors ezibuthathaka, izinto ze-magnetic, okanye uvavanyo lokuthobela imithetho, izinto ezisisiseko zeqonga labo lokuhlola zinokuba ngumahluko phakathi kwedatha ethembekileyo kunye neziphumo ezonakeleyo.

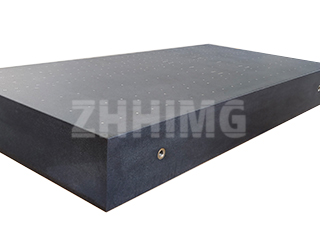

Apha kwi-ZHHIMG, siyayiqonda le khonkco ibalulekileyo. Iinxalenye zethu ze-Precision Granite azikhethwanga nje ngenxa yokuba zithe tyaba kwaye ziqinile; zikhethwa ngenxa yokukwazi kwazo ukumelana nokuphazamiseka kwemagnethi, nto leyo ezenza zibe lolona khetho lubalaseleyo kunezixhobo zemveli ezifana nentsimbi ephosiweyo okanye intsimbi.

Inzuzo EngeyoMagnetic yeGranite Yendalo

Ukusebenza kakuhle kwegranite njengeqonga elichasene nemagnethi kuvela kwindlela eyakhiwe ngayo i-geological. I-Black Granite esemgangathweni ophezulu lilitye eliyi-igneous elenziwe kakhulu ziiminerali ze-silicate, ezifana ne-quartz kunye ne-feldspar, ezingezizo imagnethi kwaye azihambisi umbane. Olu lwakhiwo lukhethekileyo lubonelela ngeenzuzo ezimbini ezicacileyo kwiindawo zovavanyo ezinobuzaza:

- Ukususa Ukuphazamiseka kweFerromagnetic: Ngokungafaniyo nesinyithi, esinokufakelwa imagnethi ngamasimi angaphandle size singenise 'inkumbulo' yemagnethi okanye impembelelo kwindawo yovavanyo, igranite ihlala ingasebenzi kakuhle ngemagnethi. Ayizukuvelisa, igcine, okanye itshintshe intsimi yemagnethi, iqinisekisa ukuba uphawu lwemagnethi kuphela olukhoyo lolwezinto ezilinganiswayo.

- Ukumisa i-Eddy Currents: Isinyithi sisixhobo sombane. Xa into eqhuba umbane ivezwe kwi-magnetic field eguquguqukayo (into eqhelekileyo kuvavanyo), ivelisa i-eddy currents ezijikelezayo ezaziwa ngokuba yi-eddy currents. Le mizila yenza eyayo i-magnetic field yesibini, ingcolisa ngokukhutheleyo indawo yokulinganisa. Njenge-insulator yombane, i-granite ayinakukwazi ukwenza le mizila iphazamisayo, ngaloo ndlela isusa umthombo omkhulu wengxolo kunye nokungazinzi.

Ngaphaya koBumsulwa beMagnetic: I-Metrology Trifecta

Nangona uphawu olungengomagnetic lubalulekile, amaqonga e-granite metrology e-ZHHIMG anikezela ngeempawu ezipheleleyo eziqinisa ubunyulu bomlinganiselo:

- Ukudambisa Ukungcangcazela Okugqwesileyo: Ulwakhiwo oluxineneyo noluncinci lwegranite yethu lufunxa ngokwendalo ukungcangcazela koomatshini kunye ne-acoustic, lunciphisa ingxolo enokonakalisa ukufundwa kwezinzwa zemagnethi ezinovakalelo olukhulu.

- Uzinzo lobushushu: I-Granite ibonisa i-coefficient ephantsi kakhulu yokwandiswa kobushushu. Oku kuthetha ukuba ngokungafaniyo nesinyithi, esinokugoba okanye sishukume ngenxa yotshintsho lobushushu (ngamanye amaxesha olubangelwa kukufudumala komsinga we-eddy), i-reference plane ye-granite igcina i-geometry yayo, iqinisekisa uzinzo lobukhulu kunye nokuphindaphinda kwe-sub-micron.

- Ukuqina Okungangeni Kumhlwa: I-Granite ayimelani ngokwemvelo nomhlwa, umhlwa, kunye neekhemikhali eziqhelekileyo, iqinisekisa ukuthembeka kunye nokuchaneka kweqonga ixesha elide ngaphandle kokubola okubonwa kwiziseko zesinyithi.

Iindawo ezifanelekileyo zeZHHIMG Granite

Ezi mpawu zenza i-ZHHIMG's precision granite ibe yiPlatform ebalulekileyo ye-Ultra-Precision kwimizi-mveliso ephambili kwihlabathi liphela. Sakha isiseko esizinzileyo sezicelo ezibalulekileyo, kuquka:

- Uvavanyo lwe-Electromagnetic Compatibility (EMC) kunye ne-EMI

- Ukulinganiswa kunye noVavanyo lweMagnetic Sensor

- Oomatshini bokulinganisa abaQokelelweyo (ii-CMM)

- Ukuhlolwa kunye nokuVeliswa kweWafer yeSemiconductor

- Ulungelelwaniso lwe-Optical kunye neeNkqubo zeLaser

Xa uvavanyo okanye imveliso yakho ifuna i-Vibration Damping Base enika ubunyulu bemagnethi kunye nozinzo olungagungqiyo, kholelwe kubuchule be-ZHHIMG kwi-Custom Granite Components ukuze inike isisombululo esifanelekileyo.

Ixesha leposi: Oktobha-14-2025