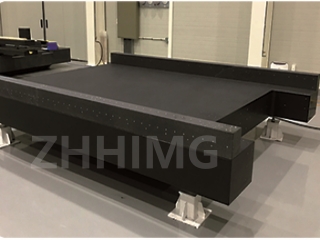

Iqonga lokuhamba kwe-gantry echanekileyo ye-XYZT lisebenzisa izinto ze-granite, ezineemfuno ezininzi ezikhethekileyo kwinkqubo yokufakela nokulungisa iimpazamo. Xa kuthelekiswa nenkqubo yokufakela izinto eziqhelekileyo, kuyimfuneko ukunika ulawulo olongezelelekileyo kwiikhonkco ezibalulekileyo ukuze kunikwe ukusebenza okugqibeleleyo kwiingenelo zayo zokusebenza ngokuchanekileyo.

Inkxaso yesiseko kunye nokulungiswa kwamanqanaba

Izinto eziqhelekileyo zinemfuno ebanzi yokuxhasa isiseko, ngelixa izinto zegranite zifuna inkxaso yesiseko eqinileyo nethe tyaba ngenxa yoxinano lwazo oluphezulu kunye nobume obubuthathaka. Ngaphambi kokufakela, qiniseka ukuba amandla okuthwala komhlaba wokufakela okanye iqonga lesiseko ubuncinane aphindwe ka-2-3 kunobunzima obupheleleyo bezixhobo, kwaye uqinisekise ukuba impazamo yokuthamba kwesiseko ilawulwa ngaphakathi kwe-±0.1mm/m ngokusebenzisa inqanaba elichanekileyo. Ngexesha lenkqubo yokufaka, isinyithi esinobungcali kunye neebholiti zokulungisa zisetyenziselwa ukulungisa kakuhle ulungelelwaniso lweqonga, ukuze ukuphambuka okuthe tye kweqonga le-XYZT kungadluli kwi-±0.05mm/m nangayiphi na indlela. Olu qhagamshelo lubalulekile, ukuphambuka okuncinci, izinto zegranite ezisetyenziswa ixesha elide zinokubangelwa kukuqhekeka kwamandla okungalingani kwendawo, okuchaphazela ukuchaneka kunye nokuzinza kweqonga.

Ukuphatha kunye nokubeka indawo

Izinto zegranite zinzima kwaye zibuthathaka, kwaye kufuneka ziphathwe ngononophelo olukhulu. Ngokungafaniyo nezinto eziqhelekileyo kunokuba lula ukuphakamisa, izinto zegranite zokuphatha kufuneka zisebenzise izixhobo zokuphakamisa zobungcali, ezixhotyiswe ngee-pad ezithambileyo zokukhusela ukuthintela ukungqubana. Kwinkqubo yokubeka, impazamo yokubeka iqonga ilawulwa ngaphakathi kwe-±0.02mm ngokusebenzisa izixhobo zokulinganisa ezichanekileyo ezifana ne-laser rangefinder kunye nesikhululo esipheleleyo. Xa kuthelekiswa neemfuno zokuchaneka kwendawo ezikhululekileyo zokufakelwa kwezinto eziqhelekileyo, indawo echanekileyo yezinto zegranite inxulumene ngokuthe ngqo nokuchaneka kwentshukumo elandelayo, ukuba indawo ayichanekanga, iya kukhokelela kuxinzelelo olungalinganiyo lwereyile yesikhokelo, isikrufu se-lead kunye nezinye izinto zothumelo, ibenze bube mandundu ukuguguleka, inciphise ubomi benkonzo yeqonga kunye nokuchaneka kwentshukumo.

Qhagamshela kwaye ulungise

Iindlela zoqhagamshelo lwezinto eziqhelekileyo ziyahluka kwaye izinga lokunyamezela iimpazamo liphezulu, ngelixa uqhagamshelo lwezinto zegranite lufuna ukuqwalaselwa ngokukodwa. Xa usebenzisa i-binder ekhethekileyo okanye uqhagamshelo loomatshini, kuyimfuneko ukusebenza ngokuhambelana neemfuno zenkqubo. Xa kusetyenziswa izincamathelisi, ubukhulu bengubo kunye nokufana kufuneka kulawulwe ngokuchanekileyo ukuqinisekisa amandla e-bond ngelixa kuthintelwa uxinano loxinzelelo olubangelwa bubukhulu be-binder obungaguqukiyo. Uqhagamshelo loomatshini kufuneka lukhethe iibholiti kunye neenati ezifanelekileyo, lulawule i-torque yokuqinisa, kwaye luthintele ukuqina okugqithisileyo okubangela ukuqhekeka kwegranite. Emva kokuba uqhagamshelo lugqityiwe, isixhobo sokubona iimpazamo ze-ultrasonic kunye nezinye izixhobo zisetyenziselwa ukubona iindawo zoqhagamshelo ukuqinisekisa ukuba akukho ziphene, kunye nokuqinisekisa uzinzo lwesakhiwo siphela seqonga kunye nokukwazi ukugcina ukuchaneka.

Ukuqaliswa kwenkqubo yombane kunye nolawulo

Kwinqanaba lokulungisa ii-electrical and control system, uvakalelo lwezinto eziqhelekileyo kwi-fine tuning ye-electrical parameters luphantsi kakhulu, kwaye iimpawu ezichanekileyo ze-granite components zifuna ukuhambelana kwee-electrical parameters ezichanekileyo ngakumbi. Kuyimfuneko ukusebenzisa isoftware yobungcali yokulungisa ii-electrical ukuze kulinganiswe kakuhle isantya se-motor, i-torque kunye nezinye ii-parameters, ukuze inkqubo yokukhawulezisa kunye nokuthomalalisa intshukumo yeqonga ihambe kakuhle kwaye igudileyo, kwaye indawo ebekwe kuyo ikhawuleze kwaye ichanekile. Ukubeka esweni imeko yentshukumo yeqonga ngexesha langempela ngokusebenzisa ii-sensors ezichanekileyo, impendulo kwinkqubo yolawulo ukuze kwenziwe ngcono kwaye kulungiswe, ukuqinisekisa ukuba iqonga linokwenziwa ngokuchanekileyo phantsi kwemiyalelo yokuhamba kwinqanaba le-micron okanye le-nanometer, ukunika ukudlala okupheleleyo kwi-high-precision potential ye-high-precision components.

Ixesha leposi: Epreli-14-2025