Kwicandelo lokuvelisa elikumgangatho ophezulu, izinto zegranite zeZHHIMG zibalasele ngomgangatho wazo ogqwesileyo, obangelwa kukulawula kwazo ngokungqongqo yonke inkqubo ukusuka ekumbeni ukuya ekucutshungulweni ngokuchanekileyo. Ngokukodwa, ukukhethwa kwegranite emnyama yendalo esemgangathweni ophezulu njengesixhobo esiphambili kuye kwabeka isiseko esiqinileyo sokwenziwa kwemveliso ibe semgangathweni.

I. Ukwembiwa Okuchanekileyo: Ulawulo Lomgangatho kumthombo

I-ZHHIMG iyazi kakuhle ukuba izinto ezisemgangathweni ophezulu zisisiseko sokufumana iimveliso ezibalaseleyo. Kwinqanaba lokuqala lokwemba, iqela leengcali zejoloji lisebenzisa iindlela eziphambili zokuhlola ukwenza uvavanyo olupheleleyo lomthombo wezimbiwa kunye nokuchonga ngokuchanekileyo iindawo ezityebileyo kwi-granite emnyama yendalo ekumgangatho ophezulu. I-granite kwezi ndawo ineenzuzo ezifana ne-dense mineral crystallization, ubulukhuni obuphezulu kunye nokungcola okuncinci, okubonelela ngesiqinisekiso esisisiseko sokucutshungulwa okulandelayo kunye nokusebenza kwemveliso.

Ngexesha lenkqubo yokwemba, kusetyenziswa ubuchwepheshe bokwemba obuphucukileyo nobunobuhlobo nokusingqongileyo, obufana nokusarha ngentambo, kusetyenziswa. Oku kuqinisekisa ukusebenza kakuhle kwemigodi ngelixa kunciphisa umonakalo kwizinto zamatye kakhulu, kuqinisekisa ukuba iibhloko eziyembiweyo zinobunono obuphezulu kunye nobume obufanayo. Kwangaxeshanye, bambelela ngokungqongqo kwingcamango yokukhuselwa kokusingqongileyo, kwaye ulahle ngokufanelekileyo inkunkuma eveliswe ngexesha lenkqubo yokwemba ukuze unciphise impembelelo kwindalo esingqongileyo. Iibhloko eziyembiweyo ziya kuthuthwa ngokukhawuleza kwiindawo zokugcina ezisemgangathweni kwaye zihlelwe kwaye zigcinwe ngokwemigangatho yomgangatho, zibonelela ngokubonelela ngezinto eziluhlaza ezicwangcisiweyo nezisemgangathweni ophezulu ukuze zicutshungulwe emva koko.

Ii. Ukucwangciswa Kwangaphambili: Ukubeka isiseko sendlela yokuqala yemigangatho

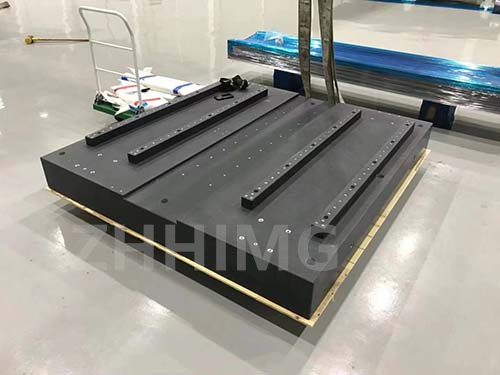

Emva kokuba izinto eziluhlaza zingene kwisityalo sokucubungula, iinkqubo zokuqala abadibana nazo kukusebenza ngomatshini nokusarha. Ngokusebenzisa izixhobo ezinkulu zokusarha ezichanekileyo, iibhloko ezinkulu zezinto eziluhlaza zisikwa zibe ziibhodi eziluhlaza ezinobukhulu obuchanekileyo ngokuhambelana neemfuno zoyilo. Ngexesha lale nkqubo, iingcali ezinamava ziya kujonga ngokusondeleyo iiparameter zokusarha ukuqinisekisa ukuba umphezulu wokusika uthambile kwaye uthe tyaba, kwaye impazamo yobukhulu ilawulwa ngaphakathi koluhlu oluncinci kakhulu.

Emva koko, kugaywa imiphetho kunye nonyango lokuqala lomphezulu. Imiphetho yebhodi erhabaxa iyagaywa kakuhle ngezixhobo zobungcali zokugaywa kwemiphetho ukuze ihlale icocekile kwaye igudile. Okwangoku, umphezulu welitye ulungiswa kwangaphambili ngeendlela ezifana nokugquma isanti kunye nokugaywa ukususa ulusu olurhabaxa, okubeka isiseko esihle sokulungiswa okucolekileyo okulandelayo.

Iii. Ukucubungula kakuhle: Ukwakha iMigangatho eBalaseleyo

Xa zingena kwinqanaba lokucubungula kakuhle, izinto zegranite ze-ZHHIMG ziqala ukubonisa umgangatho wazo ongaqhelekanga. Iinkqubo zokusika nokwenza zisebenzisa izixhobo zokusika ze-CNC eziphambili. Ngokusekelwe kwimizobo yoyilo echanekileyo, iipleyiti ezirhabaxa zinqunyulwa zibe zizinto ezihlangabezana neemfuno ezahlukeneyo zemilo enzima. Itekhnoloji yokubeka kunye nokusika ngokuchanekileyo kwezixhobo iqinisekisa ukuba impazamo yobukhulu bezinto ayidluli kwi-±0.1mm, ihlangabezana neemfuno ezingqongqo zokuchaneka kobukhulu kwicandelo lokuvelisa eliphezulu.

Kwizixhobo ezineemfuno ezikhethekileyo zokuhombisa okanye zokusebenza, kuya kwenziwa unyango lokukrola nokuhombisa. Iingcali zobugcisa ezinamava okanye oomatshini bokukrola be-CNC abaphambili banokukrola ngokuchanekileyo iipateni ezintle, iimpawu okanye izakhiwo ezisebenzayo kumphezulu wezixhobo, nto leyo eyonyusa ixabiso elongezelelweyo kunye nokusebenza kakuhle kwezixhobo.

Iv. Ukulungiswa emva kokulungiswa: Ukupolisha umgangatho ogqibeleleyo

Izixhobo ezicociwe kakuhle ziya kupholishwa kwaye zigqitywe umphezulu. Ngeenkqubo ezininzi zokupholishwa kakuhle kunye nokudityaniswa nezixhobo zokupholishwa zobungcali, umphezulu wezixhobo zegranite ufikelela kwinqanaba eliphezulu lokuguda, kunye nokukhazimla okufanayo kunye nokuhlala ixesha elide. Oku akupheleli nje ekuphuculeni ubuhle bezixhobo, kodwa kukwaphucula ukusebenza kwazo okuchasene nokungcoliswa kunye nokusebenza okunganyangekiyo.

Uhlolo olungqongqo kunye nolawulo lomgangatho luhamba kuyo yonke inkqubo. Amaqela ovavanyo lomgangatho wobungcali enza uvavanyo olupheleleyo kwiziphene zenkangeleko, ukuchaneka kobukhulu, ukuthamba, iimpawu zomzimba kunye nezinye iinkalo zezixhobo ngokuhambelana nemigangatho ephezulu yamazwe ngamazwe neyeshishini. Akukho siphako sincinci esinokusinda "emehlweni abukhali" abahloli bomgangatho. Kuphela ziimveliso ezihlangabezana ngokupheleleyo nemigangatho eziya kuvunyelwa ukuba zingene kwinkqubo yokupakisha.

V. Ukupakishwa kunye nokuThuthwa: Isiqinisekiso sokuhanjiswa kokhuseleko

Izinto zegranite ze-ZHHIMG eziye zahlolwa ngokungqongqo izihlandlo ezininzi ziya kusongwa ngononophelo ngezinto zokupakisha ezenzelwe wena ngobuchule. Ngokwemilo, ubungakanani kunye nobuthathaka bezinto, izinto ze-buffer, iifreyimu zokukhusela, njl.njl. ziyahambelana ukuqinisekisa ukuba izinto zikhuselekile ngokupheleleyo ngexesha lokuthuthwa. Emva koko, ngokuhambelana neemfuno zeodolo yomthengi, khetha indlela efanelekileyo yokuthutha ukuze uhambise iimpahla kwindawo oya kuyo ngexesha elifanelekileyo nangendlela ekhuselekileyo.

Ukususela ekumbeni ukuya ekucutshungulweni ngokuchanekileyo, i-ZHHIMG ibisoloko ibambelele ekufuneni umgangatho ongagungqiyo, ikhetha i-granite emnyama yendalo ekumgangatho ophezulu kwaye yenza icandelo ngalinye le-granite ngobuchule obugqwesileyo kunye nemigangatho engqongqo, ibonelela ngeemveliso ezithembekileyo nezisemgangathweni ophezulu kwicandelo lemveliso elikumgangatho ophezulu kwihlabathi liphela.

Ixesha leposi: Meyi-13-2025