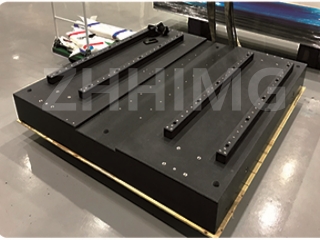

Izixhobo zomatshini wegranite ezenziwe ngokwezifiso zineendawo ezahlukeneyo zokusetyenziswa ngenxa yeempawu ezahlukeneyo kunye neempawu abanazo. Ezi zixhobo zomatshini wegranite zenziwe ngezinto zegranite ezikumgangatho ophezulu, ezaziwa ngokuqina kwayo, ubulukhuni, kunye nokumelana nokuguguleka. Ke ngoko, zisetyenziswa kakhulu kumashishini ahlukeneyo afuna ukuchaneka okuphezulu kunye nokuchaneka kwimisebenzi yawo. Kweli nqaku, siza kujonga ezinye zeendawo zokusetyenziswa kwezixhobo zomatshini wegranite ezenziwe ngokwezifiso.

1. Ishishini loBunjineli obuchanekileyo

Izixhobo zomatshini wegranite ezenziwe ngokwezifiso zisetyenziswa kakhulu kushishino lobunjineli bokuchaneka, oluquka amashishini ezonyango, eemoto, eendiza, kunye ne-elektroniki. Zisetyenziswa njengeepleyiti zesiseko, iitafile zomsebenzi, kunye nezixhobo zokulinganisa kwizixhobo zomatshini ezichaneke kakhulu. Igranite inika uzinzo oluphezulu, oluyimfuneko kushishino lokuchaneka ukuze kufezekiswe ukuchaneka okufunekayo, kwaye ikwamelana neemeko zokusingqongileyo ezifana notshintsho lobushushu kunye nokungcangcazela.

2. Ishishini leMetroloji

Izixhobo zomatshini wegranite ezenziwe ngokwezifiso zikwasetyenziswa kwishishini le-metrology, elibandakanya ukulinganisa kunye nokulinganisa iimpawu ezinobukhulu kunye nejometri. Izixhobo zomatshini wegranite zisetyenziswa njengeziseko zokulinganisa, iipleyiti zomphezulu, kunye nemigangatho yokulinganisa izixhobo zomatshini. Uzinzo oluphezulu kunye neempawu ezithe tyaba zegranite zinceda ekufezekiseni ukuchaneka kokulinganisa okuphezulu, okubalulekileyo kwishishini le-metrology.

3. Ishishini lokuPakisha

Ishishini lokupakisha libandakanya ukuveliswa kwezinto ezahlukeneyo zokupakisha ezifana neebhokisi, iibhotile, kunye nezikhongozeli. Izixhobo zomatshini wegranite ezenziwe ngokwezifiso zisetyenziswa kwiimashini zokupakisha ezifana noomatshini bokugcwalisa, oomatshini bokuvala, kunye noomatshini bokulebhelisha. Izixhobo zegranite zibonelela ngozinzo oluphezulu kunye nokumelana nokuguguleka, okunceda ukuphucula ukusebenza kakuhle kwenkqubo yokupakisha kunye nokunciphisa ixesha lokungasebenzi.

4. Ishishini leeglasi

Ishishini leglasi libandakanya ukuveliswa kweemveliso ezahlukeneyo zeglasi ezifana namaphepha, iibhotile, kunye nezikhongozeli. Izixhobo zomatshini wegranite ezenziwe ngokwezifiso zisetyenziswa kwizixhobo zokwenza iglasi, ezinje ngoomatshini bokusika nokupolisha iglasi. Ubunzima obuphezulu kunye nokumelana nokuguguleka kwegranite kunceda ukuphucula ukuchaneka nokusebenza kakuhle kwenkqubo yokwenza iglasi.

5. Ishishini le-Semiconductor

Ishishini le-semiconductor libandakanya ukuveliswa kwezinto ze-elektroniki ezifana nee-microchips kunye neesekethe ezidibeneyo. Izinto zomatshini we-granite ezenziwe ngokwezifiso zisetyenziswa kwizixhobo zokwenza i-semiconductor, ezifana noomatshini bokuhlola i-wafer kunye noomatshini be-lithography. Uzinzo oluphezulu kunye nokuthamba kwe-granite kunceda ekufezekiseni ukuchaneka okuphezulu kunye nokuchaneka kwinkqubo yokuvelisa.

6. Ishishini lokutya

Ishishini lokutya libandakanya ukuveliswa kweemveliso ezahlukeneyo zokutya ezifana nezidlo ezikhawulezayo, iziselo, kunye neemveliso zobisi. Izixhobo zomatshini wegranite ezenziwe ngokwezifiso zisetyenziswa kwizixhobo zokulungisa ukutya, ezifana noomatshini bokusika nokugaya. Ubunzima obuphezulu kunye nokumelana nokuguguleka kwegranite kunceda ukuphucula ukusebenza kakuhle kunye nococeko lwenkqubo yokulungisa ukutya.

Ukuqukumbela, izinto zomatshini wegranite ezenziwe ngokwezifiso zinoluhlu olubanzi lweendawo zokusetyenziswa, kubandakanya ubunjineli bokuchaneka, i-metrology, ukupakisha, iglasi, i-semiconductor, kunye namashishini okutya. Ezi zinto zibonelela ngozinzo oluphezulu, ukuchaneka, kunye nokumelana nokuguguleka, ezibalulekileyo kumashishini ahlukeneyo afuna ukuchaneka okuphezulu kunye nokuchaneka kwimisebenzi yawo. Ukutyala imali kwizinto zomatshini wegranite ezenziwe ngokwezifiso kunokunceda amashishini aphucule ukusebenza kwawo, anciphise ixesha lokungasebenzi, kwaye anyuse inzuzo.

Ixesha lokuthumela: Oktobha-13-2023