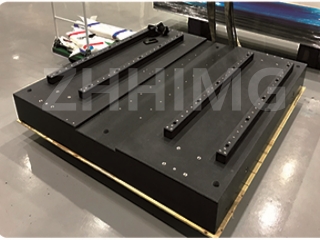

Amacandelo omatshini we-granite oqhelekileyo anoluhlu olubanzi lweendawo zokusetyenziswa ngenxa yeempawu ezahlukeneyo kunye neempawu abanazo.Ezi zixhobo zomatshini we-granite zenziwe nge-granite esemgangathweni ophezulu, eyaziwayo ngokuhlala kwayo, ukuqina, kunye nokuchasana nokugqoka kunye nokukrazula.Ke ngoko, zisetyenziswa ngokubanzi kumashishini ahlukeneyo afuna ukuchaneka okuphezulu kunye nokuchaneka kwimisebenzi yawo.Kweli nqaku, siza kujonga ezinye zeendawo zokusetyenziswa kwamacandelo omatshini wegranite yesiko.

1. UShishino lobuNjineli obuchanekileyo

Amacandelo omatshini we-granite oqhelekileyo asetyenziswa ngokubanzi kwishishini lobunjineli obuchanekileyo, elibandakanya amayeza, iimoto, i-aerospace, kunye namashishini ombane.Zisetyenziswa njengesiseko sepleyiti, iitafile zokusebenza, kunye namacandelo okulinganisa kwizixhobo zomatshini ezichanekileyo.I-Granite inikezela ukuzinza okuphezulu, okuyimfuneko kwishishini elichanekileyo ukufezekisa ukuchaneka okufunwayo, kwaye iphinda ixhathise kwizinto ezisingqongileyo ezifana nokutshintsha kweqondo lokushisa kunye nokunyakaza.

2. Ishishini leMetrology

Amacandelo omatshini wegranite oqhelekileyo nawo asetyenziswa kwishishini le-metrology, elibandakanya umlinganiselo kunye nokulinganisa iimpawu ze-dimensional kunye nejometri.Amacandelo omatshini weGranite asetyenziswa njengeziseko zokulinganisa, iipleyiti zangaphezulu, kunye nemigangatho yokulinganisa izixhobo zomatshini.Uzinzo oluphezulu kunye neempawu ezithe tyaba zegranite zinceda ukufezekisa ukuchaneka komlinganiselo ophezulu, oyimfuneko kwishishini le-metrology.

3. Ishishini lokuPakisha

Umzi-mveliso wokupakisha ubandakanya ukuveliswa kwezinto ezahlukeneyo zokupakisha ezinje ngeebhokisi, iibhotile kunye nezikhongozeli.Amacandelo omatshini oqhelekileyo we-granite asetyenziswa kumatshini wokupakisha njengoomatshini bokuzalisa, oomatshini bokutywina, kunye noomatshini bokubhala.Amacandelo e-granite anika ukuzinza okuphezulu kunye nokuxhatshazwa kokugqoka, okunceda ukuphucula ukusebenza kakuhle kwenkqubo yokupakisha kunye nokunciphisa ixesha lokuphumla.

4. Ishishini leglasi

Ishishini leglasi libandakanya ukuveliswa kweemveliso zeglasi ezahlukeneyo ezinje ngamashiti, iibhotile, kunye nezikhongozeli.Amacandelo omatshini we-granite asetyenziswa kwisixhobo sokwenza iglasi, njengokusika iglasi kunye noomatshini bokupolisha.Ubunzima obuphezulu kunye nokumelana nokugqoka kwegranite kunceda ukuphucula ukuchaneka kunye nokusebenza kakuhle kwenkqubo yokuvelisa iglasi.

5. Ishishini leSemiconductor

Ishishini le-semiconductor libandakanya ukuveliswa kwamacandelo e-elektroniki afana ne-microchips kunye neesekethe ezidibeneyo.Amacandelo omatshini oqhelekileyo wegranite asetyenziswa kwisixhobo sokwenza i-semiconductor, njengoomatshini bokuhlola i-wafer kunye noomatshini be-lithography.Ukuzinza okuphezulu kunye ne-flatness ye-granite inceda ukufezekisa ukuchaneka okuphezulu kunye nokuchaneka kwindlela yokuvelisa.

6. Ishishini lokutya

Ishishini lokutya libandakanya ukuveliswa kwemveliso yokutya eyahlukahlukeneyo njengamashwamshwam, iziselo kunye neemveliso zobisi.Amacandelo omatshini oqhelekileyo we-granite asetyenziswa kwisixhobo sokwenza ukutya, njengokusika kunye noomatshini bokugaya.Ubunzima obuphezulu kunye nokumelana nokunxiba kwegranite kunceda ukuphucula ukusebenza kakuhle kunye nococeko lwenkqubo yokulungisa ukutya.

Ukuqukumbela, amacandelo omatshini wegranite yesiko anoluhlu olubanzi lweendawo zokusetyenziswa, kubandakanya ubunjineli obuchanekileyo, i-metrology, ukupakishwa, iglasi, i-semiconductor, kunye namashishini okutya.Ezi zixhobo zibonelela ngokuzinza okuphezulu, ukuchaneka, kunye nokuxhatshazwa kokugqoka, okuyimfuneko kumashishini ahlukeneyo afuna ukuchaneka okuphezulu kunye nokuchaneka kwimisebenzi yabo.Utyalo-mali kumatshini wegranite yesiko lunokunceda amashishini aphucule ukusebenza kwawo kakuhle, ukunciphisa ixesha lokuphumla, kunye nokwandisa inzuzo.

Ixesha lokuposa: Oct-13-2023