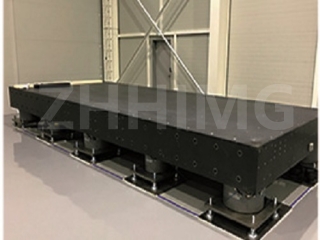

Xa kufikwa ekwenzeni iimveliso zokucubungula i-wafer, isiseko somatshini sibaluleke njengayo nayiphi na enye inxalenye. Isiseko esomeleleyo nesizinzileyo sibalulekile ukuqinisekisa ukuchaneka kwenkqubo yokugaya nokuthintela nawuphi na umonakalo kwizinto ezinobuthathaka. Nangona isinyithi siyindlela eqhelekileyo yokukhetha iziseko zomatshini, i-granite yindlela ethandwayo ngakumbi ngenxa yeempawu zayo ezizodwa. Nazi ezinye zezizathu zokuba i-granite isenokuba lukhetho olungcono kunesinyithi kwisiseko somatshini we-granite.

1. Uzinzo kunye nokuqina

I-granite inobunzima obukhulu kunye nokuqina kuneentsimbi ezininzi, oko kuthetha ukuba inokumelana ngcono nokungcangcazela kunye nokuhamba. Oku kubaluleke kakhulu kwizicelo zomatshini we-wafer, apho nokungcangcazela okanye ukuhamba okuncinci kunokubangela ukungachaneki okanye iziphene kwiimveliso ezigqityiweyo. Uzinzo kunye nokuqina kwe-granite kuyenza ibe yinto efanelekileyo kwiziseko zoomatshini ezifuna ukuchaneka okuphezulu.

2. Ukumelana notshintsho lobushushu

Enye yezona nzuzo ziphambili zegranite kuneesinyithi kukuba iyakwazi ukumelana notshintsho lobushushu kunye notshintsho. Oku kubalulekile ekucutshungulweni kwe-wafer, apho ubushushu bunokutshintshatshintsha kakhulu ngexesha lenkqubo yokwenziwa. Ngokungafaniyo neesinyithi ezinokwanda okanye zinciphe ngotshintsho lobushushu, igranite igcina imo kunye nobukhulu bayo, iqinisekisa ukusebenza okuthembekileyo nokungaguquguqukiyo.

3. Ukuqina kunye nobude bexesha

I-Granite yenye yezona zinto zinzima ezikhoyo, nto leyo eyenza ukuba ingabi nakonakala, ikrazuke kwaye yonakale kakhulu. Oku kwenza ukuba ibe yeyona nto ifanelekileyo kwiziseko zoomatshini ezifuna ukumelana nemithwalo enzima okanye ukusetyenziswa rhoqo. Nokuba emva kweminyaka emininzi yokusetyenziswa, isiseko somatshini we-granite siya kugcina uzinzo, ukuqina, kunye nokuchaneka kwaso, sibonelela ngokusebenza okuzinzileyo nokuthembekileyo ngokuhamba kwexesha.

4. Iipropati ezingezizo zemagnethi

Ngokungafaniyo neentsimbi, i-granite ayinamandla ombane, nto leyo ibalulekileyo kwizicelo zokucubungula i-wafer apho ukuphazamiseka kwe-magnetic kunokubangela umonakalo omkhulu. Isiseko somatshini we-granite siqinisekisa ukuba amasimi ombane awakho kwindawo yokwenziwa kwe-machining, nto leyo enciphisa umngcipheko wokuphazamiseka kwaye iphucula ukuchaneka kwenkqubo yokwenziwa kwe-machining.

5. Kulula ukuyigcina nokuyicoca

I-granite kulula ukuyicoca nokuyigcina ikwimeko entle, nto leyo ibalulekileyo xa kusetyenzwa i-wafer apho ucoceko lubaluleke kakhulu. Ngokungafaniyo neentsimbi, i-granite ayidli mhlwa, ayidli mhlwa, okanye ayingcolisi, nto leyo ethetha ukuba ayifuni ukugcinwa nokucoca okuncinci. Ukucocwa rhoqo kuya kuqinisekisa ukuba umatshini usebenza kakuhle, ubonelela ngomatshini ochanekileyo nothembekileyo ubomi bonke.

Ukuqukumbela, nangona iintsimbi bezisoloko ziyindlela eqhelekileyo yokukhetha iziseko zoomatshini, igranite yindlela ethandwayo ngakumbi ngenxa yeempawu zayo ezizodwa. Ukukhetha isiseko somatshini wegranite kunesesinyithi kunokuba neengenelo ezibalulekileyo, kubandakanya ukuzinza, ukuqina, ukumelana notshintsho lobushushu, ukuqina, iimpawu ezingezizo zemagnethi, kunye nokulula kokugcinwa. Ukuba ukuchaneka, ukuthembeka, kunye nobude bexesha kubaluleke kakhulu kwisicelo sakho sokulungisa i-wafer, igranite ngokuqinisekileyo ifanelekile ukuqwalaselwa.

Ixesha lokuthumela: Novemba-07-2023