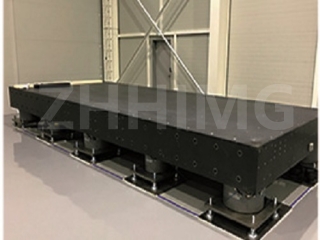

Xa kuziwa kwimveliso yokwenziwa kweemveliso ze-wafer, isiseko somatshini sibaluleke njengayo nayiphi na enye indawo.Isiseko esomeleleyo, esizinzile siyimfuneko ukuze kuqinisekiswe ukuchaneka kwenkqubo yomatshini kunye nokuthintela nawuphi na umonakalo kumacandelo abuthathaka.Ngelixa isinyithi lukhetho oluqhelekileyo kwiziseko zoomatshini, igranite yeyona nto ithandwayo ngenxa yeempawu zayo ezizodwa.Nazi ezinye zezizathu zokuba kutheni i-granite ingaba yinto engcono kunentsimbi yesiseko somatshini wegranite.

1. Ukuzinza kunye nokuqina

I-Granite inoxinano oluphezulu kakhulu kunye nokuqina kunezinyithi ezininzi, oku kuthetha ukuba inokumelana ngcono nokungcangcazela kunye nokunyakaza.Oku kubaluleke kakhulu kwizicelo zokwenziwa kwe-wafer machining, apho ukungcangcazela okuncinci okanye ukunyakaza kunokubangela ukungachaneki okanye iziphene kwiimveliso ezigqityiweyo.Ukuzinza kweGranite kunye nokuqina kwenza kube yinto efanelekileyo kwiziseko zomatshini ezifuna ukuchaneka ngokugqithiseleyo.

2. Ukumelana nokutshintsha kweqondo lokushisa

Enye yeenzuzo eziphambili zegranite phezu kweentsimbi kukukwazi ukumelana nokutshintsha kobushushu kunye nokuhluka.Oku kubalulekile ekuqhubeni i-wafer, apho ubushushu bunokuguquguquka kakhulu ngexesha lenkqubo yokuvelisa.Ngokungafaniyo neentsimbi ezinokuthi zandise okanye zivumelane nokutshintsha kweqondo lokushisa, i-granite igcina imilo kunye nobukhulu bayo, iqinisekisa ukusebenza okuthembekileyo kunye nokuhambelana.

3. Ukuqina kunye nokuphila ixesha elide

I-Granite yenye yezona zinto zinzima ezikhoyo, iyenza ukuba ixhathise ngokugqithisileyo ukunxiba, ukukrazuka, kunye nomonakalo.Oku kuyenza ibe yinto efanelekileyo kwiziseko zoomatshini ezifuna ukumelana nemithwalo enzima okanye ukusetyenziswa rhoqo.Nangona emva kweminyaka yokusetyenziswa, isiseko somatshini we-granite siya kugcina ukuzinza, ukuqina, kunye nokuchaneka, ukubonelela ngokuqhubekayo kunye nokusebenza okuthembekileyo ngexesha.

4. Iimpawu ezingenamagnetic

Ngokungafaniyo nesinyithi, i-granite ayiyo-magnetic, eyimfuneko kwi-wafer processing applications apho ukuphazamiseka kwemagneti kunokubangela umonakalo omkhulu.Isiseko somatshini we-granite siqinisekisa ukuba iindawo zamagnetic azikho kwindawo yomatshini, okunciphisa umngcipheko wokuphazamiseka kunye nokuphucula ukuchaneka kwenkqubo yomatshini.

5. Kulula ukuyigcina kwaye icocekile

I-Granite kulula ukuyicoca kunye nokugcinwa kwayo, okuyimfuneko kwi-wafer processing applications apho ucoceko lubalulekile.Ngokungafaniyo nesinyithi, i-granite ayigqwali, i-rust, okanye ingcolise, oku kuthetha ukuba ifuna ukulungiswa okuncinci kunye nokucoca.Ukucoca rhoqo kunye nokugcinwa kuya kuqinisekisa ukuba umatshini usebenza ngokufanelekileyo, ukubonelela ngomatshini ochanekileyo nothembekileyo kwixesha elide lokuphila.

Ukuqukumbela, ngelixa iintsimbi ziye zaba lukhetho lwemveli kwiziseko zoomatshini, igranite yeyona nto ithandwayo ngenxa yeempawu zayo ezizodwa.Ukukhetha isiseko somatshini wegranite ngaphezu kwentsimbi kunokuba neenzuzo ezibalulekileyo, kubandakanya ukuzinza, ukuqina, ukuchasana nokutshintsha kobushushu, ukuqina, iipropathi ezingezizo-magnetic, kunye nokulula kokugcinwa.Ukuba ukuchaneka, ukuthembeka, kunye nokuphila ixesha elide kubaluleke kakhulu kwisicelo sakho sokucwangcisa i-wafer, i-granite ngokuqinisekileyo ifanele ukuqwalaselwa.

Ixesha lokuposa: Nov-07-2023